|

| |

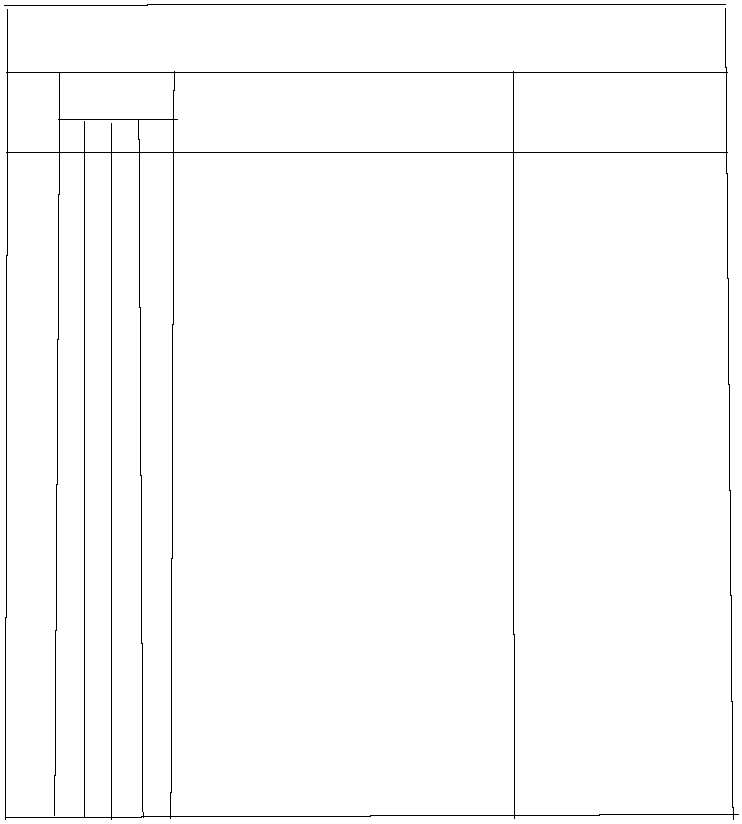

TM 1-1730-231-13&P

Table 3-1. Inspection Requirements (Continued)

INTERVAL DEFINITIONS

D - DAILY Q - QUARTERLY S - SEMI-ANNUALLY A - ANNUALLY

INTERVAL

ITEM

ITEM TO BE INSPECTED/PROCEDURE:

EQUIPMENT IS NOT

NO.

CHECK FOR AND HAVE REPAIRED,

READY/AVAILABLE IF:

D

Q

S

A

FILLED, OR ADJUSTED AS NEEDED

9

x

Relief valve adjusted properly.

Not delivering

correct pressure

due to incorrect

relief valve

setting.

MOTOR AND PUMP ASSEMBLY

10

x

Inspect motor brushes for

DC motor brushes

condition - if worn out,

worn out.

replace brushes.

11

x

Pump not turning freely.

Pump is damaged.

12

x

Flexible coupling rubber spider

Flexible coupling

is damaged or worn out.

is damaged.

HYDRAULIC RESERVOIR TANK

13

x

Check fluid level.

Fluid level is

below OPNL LEVEL

sight glass.

14

x

Inspect internal reservoir

Contamination

tank by opening cover; clean

exists.

strainer.

15

x

Check filler/breather cap and

screen for presence and

condition.

16

x

Check the four sight glasses

Sight glass is

for leaks or cracks.

broken.

HYDRAULIC PIPING ASSEMBLY

17

x

Hydraulic line connections for

tightness/leaks.

3-4

|