|

|||

|

|

|||

|

Page Title:

Chapter 3. OPERATOR'S AND ORGANIZATIONAL MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 55-1730-202-14

OPERATOR'S AND ORGANIZATIONAL MAINTENANCE

INSTRUCTIONS

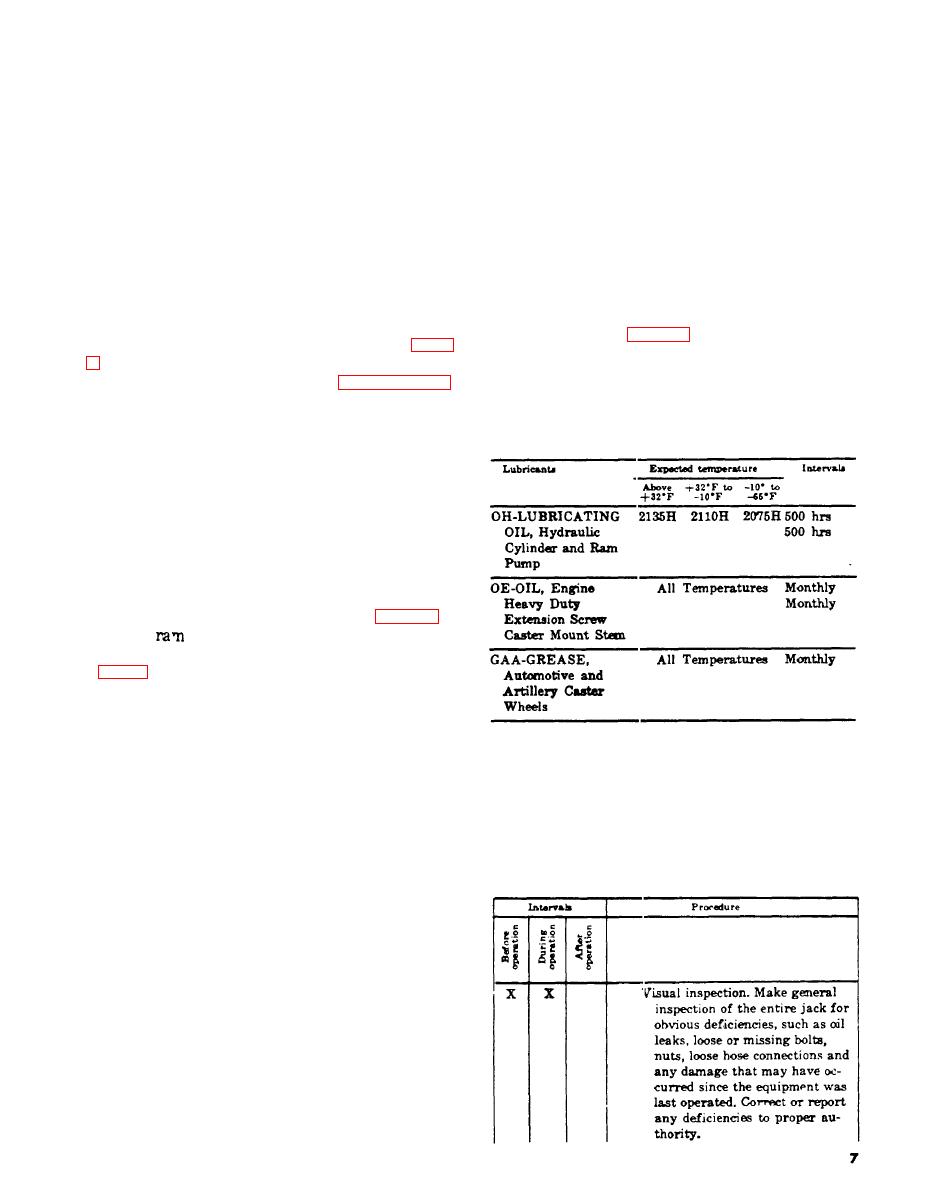

LUBRICATION

Section I.

23. GENERAL.

grease the caster wheels in accordance with the

l u b r i c a t i o n chart (table 1).

This section contains a lubrication chart (table

( 3 ) Increase the interval of steps (1) and

( 2 ) above when operating under unusual condi-

cation information contained in paragraph 24.

t i o n s , paying particular attention to thorough

cleaning prior to lubrication.

bricant containers after use and store in a clean,

d r y place. Keep all containers used for handling

o i l clean and ready for use.

b. Cleaning. Clean all lubrication fittings or

p o i n t s of application with a cloth dampened in

cleaning solvent (Federal Specification P-D-

680) before applying lubricant.

c. Points of Application.

(1) Clean the extension screw (2, figure 1)

(3) thoroughly and apply lubri-

and the

c a t i n g oil as directed in the lubrication chart

( 2 ) Apply l u b r i c a t i n g o i l t o t h e c a s t e r

m o u n t s t e m o f t h e foot assemblies (12 ) and

Section Il. PREVENTIVE MAINTENANCE SERVICES

al

maintenance.

Responsibility

for

performance

25. GENERAL.

of preventive maintenance services rests not only

To ensure the equipment is ready for opera-

w i t h the operator, but with the entire chain of

t i o n at all times, it must be inspected system-

command from section chief to commanding offi-

a t i c a l l y before operation, during operation, and

cer (AR 750-5).

after operation, so defects may be discovered and

corrected before they result in serious damage or

26. OPERATOR'S DAILY SERVICES.

f a i l u r e . The necessary preventive maintenance

services must be performed before operation. De-

fects discovered during operation of the unit will

he noted for future correction, to be made as

soon as operation has ceased. Stop operation im-

mediately if a deficiency is noticed during oper-

a t i o n which would damage the equipment if op-

e r a t i o n was continued. After-operation services

will be performed at intervals based on the nor-

m a l operation of the equipment. Reduce interval

to compensate for abnormal conditions. Defects

or unsatisfactory operating characteristics beyond

t h e scope of the operator to correct must be re-

p o r t e d at the earliest opportunity organization-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |