|

|||

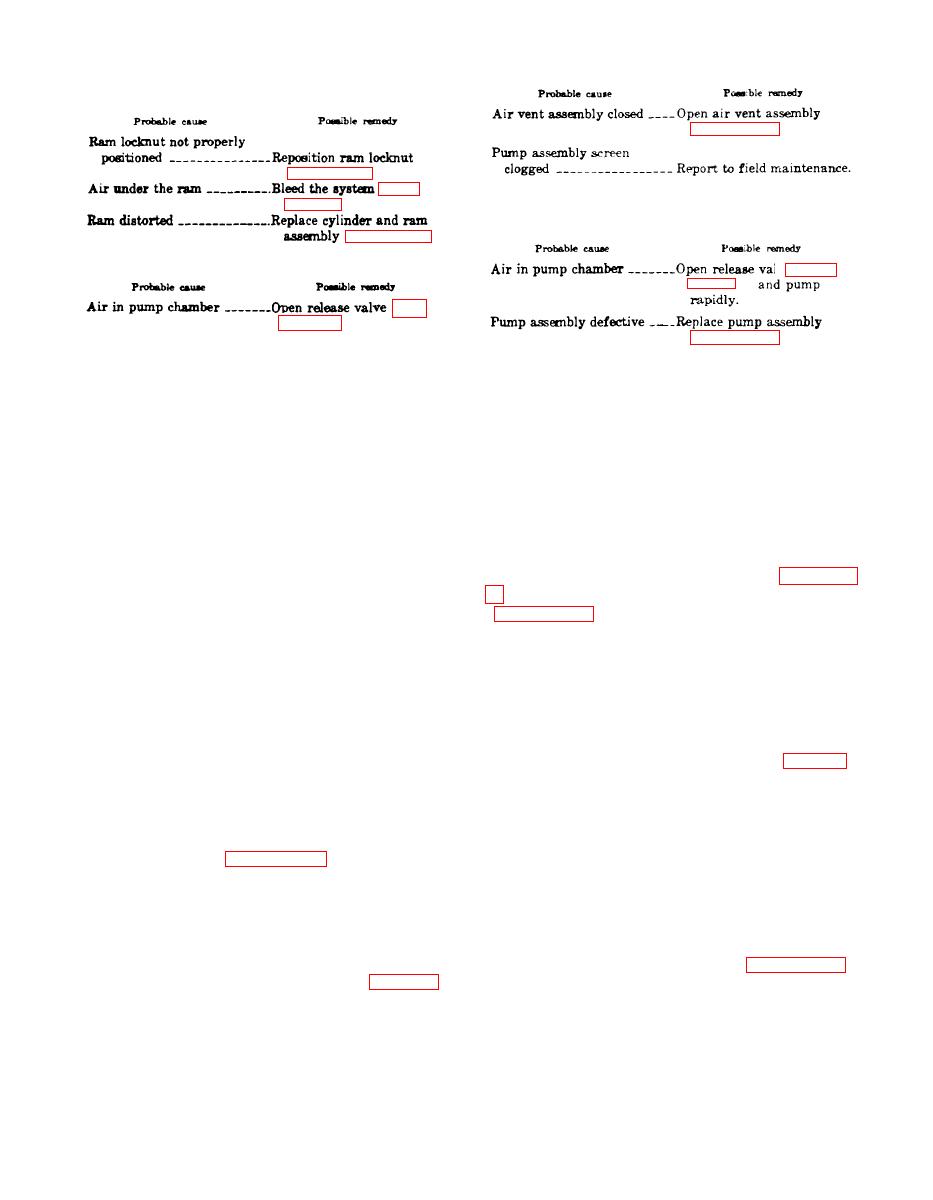

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-1730-202-14

(paragraph 19).

RESERVOIR.

Section IV. HYDRAULIC SYSTEM

(2) Release the clamp assembly (14) and re-

37. GENERAL.

move the pump from the foot assembly (12).

The hydraulic system of the tripod hydraulic

b. Installation.

jack consists of the pump assembly, cylinder and

ram assembly, and the connecting hose assembly,

(1) Install the pump assembly (13) on the

The pump is a reciprocating piston type unit, in-

foot assembly ( 12) and secure with the clamp

corporating ball inlet and discharge valves. Two

assembly (14).

adjustable relief valves are included to maintain

(2) Couple the hose assembly to the pump.

an operating pressure of 1750 psi. The cylinder

and ram assembly transforms the hydraulic oil

(3) Fill the reservoir with oil (paragraph

pressure of the pump into a vertical lifting force.

This is effected by the ram, which is caused to

rise by the incoming oil at the bottom of the

cylinder. An O-ring packing is used for an oil

40. CYLINDER AND RAM ASSEMBLY.

seal between the ram and the cylinder wall.

a. Removal

(1) Uncouple the quick disconnect fitting

of the nose at the pump assembly.

Air under the ram, indicated by springiness of

(2) Remove the nine nuts and bolts that se-

t h e ram or slowness in starting to rise, can

cure the cylinder and ram assembly (5, figure 1)

usually be removes by loosening the hose con-

ill the tripod assembly and remove the cylinder

nection at the cylinder and ram assembly and

and ram assembly.

actuating the pump. Tighten the hose connection

when the air bubbles no longer appear. If the

(3) Remove the hose assembly from the bet.

condition persists, refill the cylinder and ram

tom of the cylinder and drain the oil.

assembly with oil (paragraph 8).

b. Installation.

(1) Place the cylinder and ram assembly (5)

in the tripod assembly and secure with the 9

a. Removal.

bolts and nuts.

(1) Uncouple the quick disconnect fitting

(2) Fill the cylinder with oil (paragraph 8)

of the hose at the pump assembly (13, figure 1).

and install the hose assembly.

Section V. STRUCTURAL MEMBERS

make up the structural members of the tripod

41. GENERAL.

hydraulic jack. These members provide the firm

The tripod assembly and the three foot assem-

foundation required to support the cylinder and

blies, along with the necessary braces and links,

ram assembly during the lifting operation.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |