|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1425-600-34-5-2

i. Repair. Those maintenance operations necessary to restore an item to serviceable condition through correction

of material damage or a specific failure. Repair may be accomplished at each category of maintenance.

j. Overhaul. Normally, the highest degree of maintenance performed by the Army in order to minimize time work

in process is consistent with quality and economy of operation. It consists of that maintenance necessary to restore an

item to completely serviceable condition as prescribed by maintenance standards in technical publications for each item

of equipment. Overhaul normally does not return an item to like new, zero mileage, or hour condition.

k. Rebuild. The highest degree of materiel maintenance. It consists of restoring equipment as nearly as possible

to new condition in accordance with original manufacturing standards. Rebuild is performed only when required by

operational considerations or other paramount factors and then only at the depot maintenance category. Rebuild reduces

to zero the hours of miles the equipment, or component thereof, has been in use.

l. Symbol. The uppercase letter placed in the appropriate column indicates the lowest level at which the particular

maintenance function is to be performed.

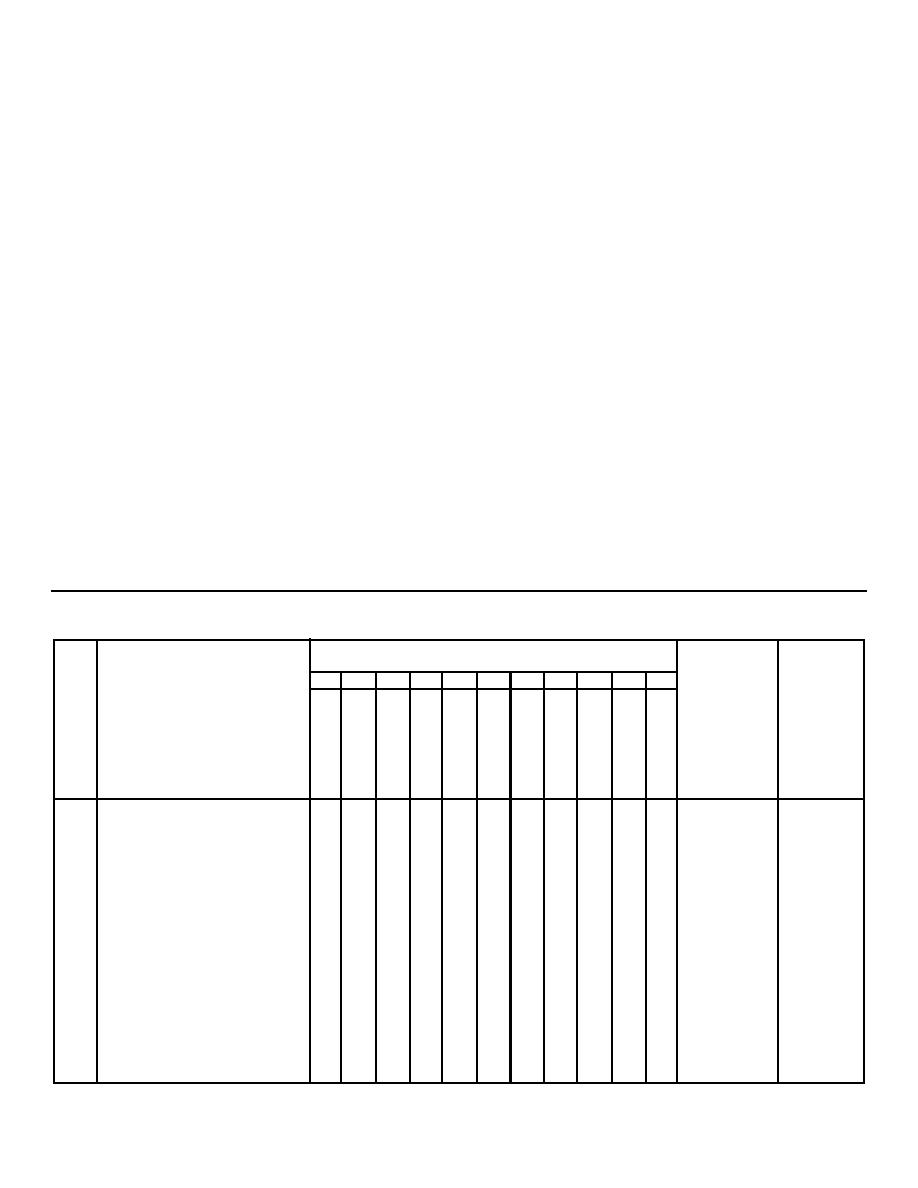

B-3. EXPLANATION OF FORMAT.

a. Column 1, Group Number. Column 1 lists group numbers, the purpose of which is to identify components,

assemblies, subassemblies, and modules with the next higher assembly.

b. Column 2, Functional Group. Column 2 lists the noun names of components, assemblies, sub-assemblies, and

modules of which maintenance is authorized.

c. Column 3, Maintenance Functions. (See MAC Chart.)

d. Column 4, Tools ,and Equipment. This column will be used to specify, by code, those tools and test equipment

required to perform the designated function.

e. Column 5, Remarks. Self-explanatory.

Section II. MAINTENANCE ALLOCATION CHART

MAINTENANCE ALLOCATION CHART

FOR

JACK, HYDRAULIC, TRIPODI 12-TON

(1)

(2)

(3)

(4)

(5)

G

Functional group

Maintenance functions

Tools and

Remarks

R

equipment

O

A

B

C

D

E

F

G

H

I

J

K

U

C

P

A

O

I

S

L

I

R

V

R

N

N

E

A

I

N

E

R

E

E

U

S

R

D

A

B

S

P

E

R

B

M

P

T

V

J

L

R

T

L

P

H

U

B

E

E

I

U

I

A

A

A

A

A

I

E

C

S

C

S

G

T

L

C

I

U

L

R

T

T

E

T

N

E

L

E

R

L

D

00

Jack, Hydraulic, Tripodi

0

0

0

0

Clean

12-ton

P-D-

01

Leg and Caster Assembly

0

0

0

0

380

Caster

0

Oil

Shaft, Caster

0

Mil-G

Spring

0

10924

02

Pump Assembly

0

0

0

0

Plunger

0

Body, Valve

0

Spring

0

Screen

0

03

Ram and Reservoir

0

0

Clean

(Assembly)

Fill

Ram

0

Mil-H

Reservoir Assembly

0

5606

16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |