|

|||

|

|

|||

|

Page Title:

Section III: OPERATING INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 55-4920-335-14

SECTION III

OPERATING INSTRUCTIONS

3-1. PREPARATION FOR STARTING. Prepare the Test

e. Remove protective caps from pressure and suction

Stand for starting and operation as follows:

hose connections (6, figure 1-2). Remove protective caps from

connection hoses. Connect hose from pressure outlet port (8,

a. Perform the daily ins pection and services outlined in

corresponding outlet on aircraft to be tested. Connect second

hose to suction port (7) and to corresponding outlet on aircraft

b. Maneuver the Test Stand to a position that is suitable

to be tested.

for hose connection to the aircraft system.

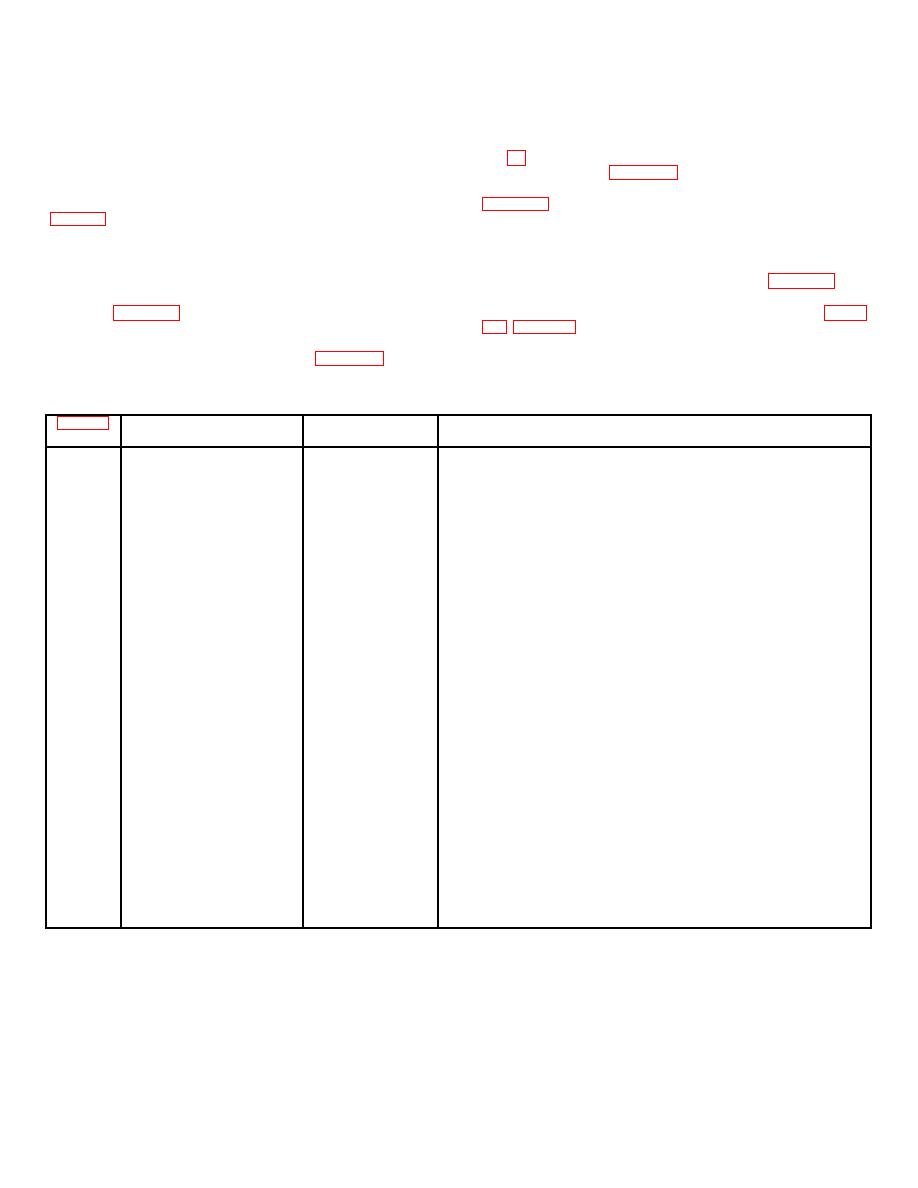

3-2. CONTROLS AND INSTRUMENTS. Table II lists,

c. When Test Stand is in position, apply hand brake

describes, and briefly explains the function of the operating

lever (11, figure 1-1) by pushing downward. Place tow bar in

controls and instruments located on the control panel (figure

upright position.

of the pump controls located in the opening beneath the control

d.

Open control panel access door (6, figure 1-1).

panel.

Table II. Control Panel Controls and Instruments

Index No.

Title

Description

Function

1

Reservoir Shutoff Valve

1 in. gate valve

Controls fluid flow from reservoir into hydraulic system.

2

30-0-30 range

Indicates generator output and/or ampere load on battery.

3

HP Gage Shutoff

Needle valve 1/4 in.

Isolates high pressure gage.

4

Gage Test Fitting

Union and cap

Testing high pressure gage.

5

HP Filter Indicator

Press-to-test

Indicates clogged HP filter when lighted.

indicator light - red

6

High Pressure Gage

0 to 6000 psi

Indicates hydraulic system pressure.

7

Flow Indicator

Variable indicator

Indicates hydraulic pump delivery from 0 to 10 gpm.

8

Fluid Level Indicator

E - 1/2 - F

Indicates fluid level in hydraulic reservoir.

9

Low Pressure Gage

30" and 0 to 150

Indicates vacuum and/or pressure in hydraulic suction system.

psi

10

LP Filter Indicator

Press-to-test

Indicates clogged LP filter when lighted.

indicator light - red

-20oF to 200F

11

Fluid Temperature Gage

Indicates temperature of fluid in hydraulic system.

12

Pressure Selector Valve

3-way valve

Connects filter pressure gage to manifold and pump suction inlet to

measure across LP filter.

13

Gage Test Fitting

Union and cap

Testing low pressure gage.

3-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |