|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-335-14

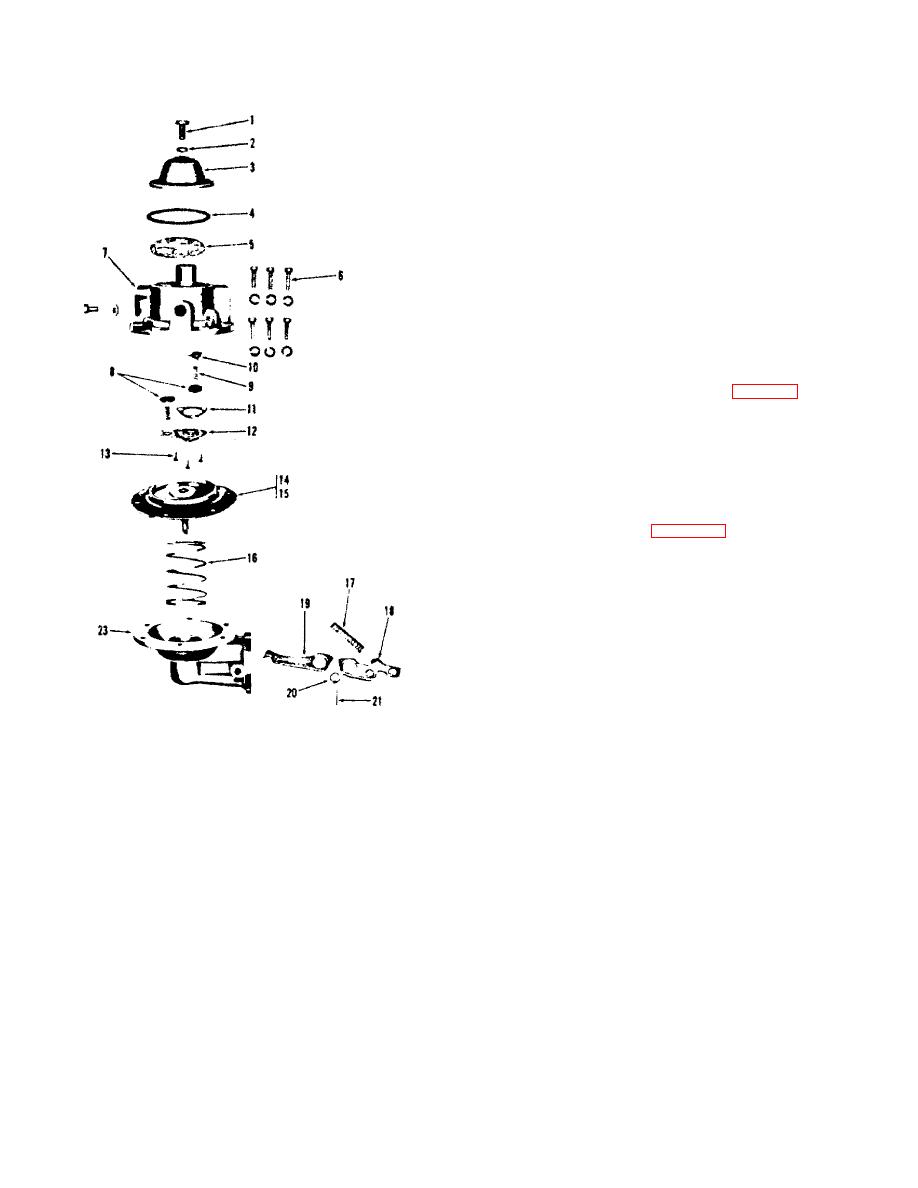

bracket (23) approximately three turns. Again crank engine

over until diaphragm (14) is pulled down into mounting bracket

(23). Tighten screws (6).

f.

Carefully clean and install filter screen (5).

g. Install gasket (4) in dome (3) and position dome onto

fuel head (7).

h. Install gasket (2) on dome bolt (1) and insert bolt in

top of dome (3) then tighten securely. Connect fuel lines and

tighten securely.

4-11. ENGINE IGNITION TIMING. If necessary to check or

retime the engine magneto, use the following procedure.

a. Remove screen over flywheel air intake opening by

taking out screws holding the screen in place. This will expose

the timing marks on flywheel and shroud (figure 4-3).

b. Remove spark plug from number 1 cylinder and turn

engine over slowly using hand crank, at the same time hold a

finger over number 1 spark plug hole so that compression

stroke can be determined by air blowing out of hole.

c. The flywheel is marked with the letters DC near one

of the air circulating vanes. This vane is further identified by an

X mark cast on the end (figure 4-3). When air blows out

number 1 spark plug hole, continue turning starting crank until

edge of marked vane on flywheel is on line with mark on

vertical centerline of shroud. Leave flywheel in this position.

At this point, keyway for mounting flywheel is also on top.

d. Remove magneto from engine. Remove fitting from

inspection hole located in gear cover at magneto mounting

flange.

e. Insert ignition cable into number 1 tower terminal of

magneto end cap and hold number 1 spark plug terminal at the

other end approximately 1/8 inch away from magneto body.

Turn magneto gear clockwise, tripping the impulse coupling

1.

Dome Bolt

13.

Screw

until number 1 terminal sparks, then hold gear in this position.

2.

Gasket

14.

Diaphragm

Install magneto on engine, meshing gears so that when

3.

Dome

15.

Gasket

magneto is in place, the gear tooth marked X will be visible

4.

Gasket

16.

Diaphragm Spring

through lower half of inspection hole in gear cover. Tighten

5.

Filter Screen

17.

Rocker Arm Spring

magneto mounting screw and nuts, making sure magneto

6.

Mounting Screw

18.

Rocker Arm

flange gasket is in place.

7.

Fuel Head

19.

Linkage

8.

Valve

20.

Rocker Arm Bushing

f. The number 1 terminal is the upper right hand tower

9.

Valve Spring

21.

Rocker Arm Pin

on the magneto cap. The terminals follow the proper firing

10.

Spring Retainer

22.

Mounting Gasket

order of 1-3-4-2 in a clockwise direction viewing the cap end.

11.

Gasket

(Not Illust)

Connect leads from magneto to spark plugs of corresponding

12.

Valve Plate

23. Mounting Bracket

number.

13.

Screw

Figure 4-2. Engine Fuel Pump

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |