|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-335-14

SECTION V

TROUBLESHOOTING

5-1. TROUBLESHOOTING. Reference to data contained in

5-2.

TROUBLESHOOTING TABLE.

Table VI is a

troubleshooting chart listing the most common operating

in diagnosis of trouble and possible remedies.

troubles, probable cause, and the remedy.

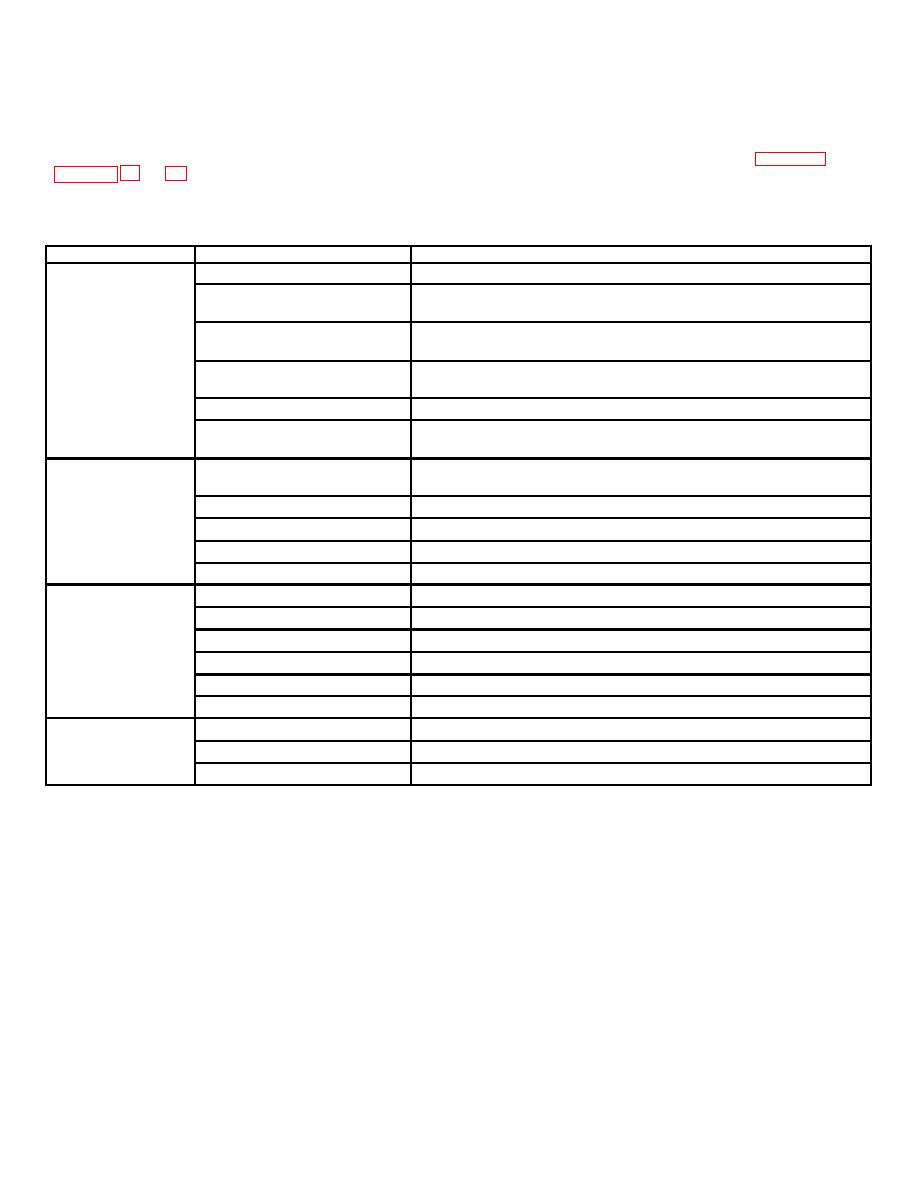

TABLE VI. Troubleshooting

Trouble

Probable Cause

Remedy

Engine will not start.

Insufficient choke on cold engine.

Choke carburetor and repeat starting procedure.

Engine flooded.

Open choke, open throttle wide and crank engine or allow a time interval

for accumulated gasoline to evaporate.

Dry off cables, replace or connect securely.

Ignition cable, broken or

disconnected.

Spark plugs wet, dirty or

Remove spark plugs, dry and clean thoroughly. Reset gap to 0.030 inch.

improperly gapped .-

Fuel supply exhausted.

Refill tank.

Breaker points pitted, dirty or out

File points, clean with lintless tape and carbon tetrachloride and adjust

of adjustment.

breaker gap.

Engine surges or

Carburetor flooding.

Choke partially closed; open choke fully.

gallops.

Sticking valves.

Remove engine for overhaul.

Defective carburetor.

Replace carburetor.

Water in fuel.

Drain water at fuel tank sump, and clean out fuel filter.

Incorrect spark plug gap.

Set plug gap at 0.030 inch.

Low oil pressure.

Low oil supply.

Refill crankcase to "FULL" mark on dip stick.

Low oil viscosity.

Drain sump, refill with correct oil.

High oil temperature.

Check engine cooling. Note particularly if ventilation inlet is clogged.

Engine bearings worn.

Remove engine for overhaul.

Oil pressure gage defective.

Replace gage.

Internal oil leaks.

Remove engine for overhaul.

High oil temperature.

Low oil supply.

Refill crankcase to "FULL" mark on dip stick.

Dirty or diluted oil.

Drain crankcase sump, refill with proper oil.

Poor engine ventilation.

Open doors. Check ventilation inlet for obstructions.

5-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |