|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

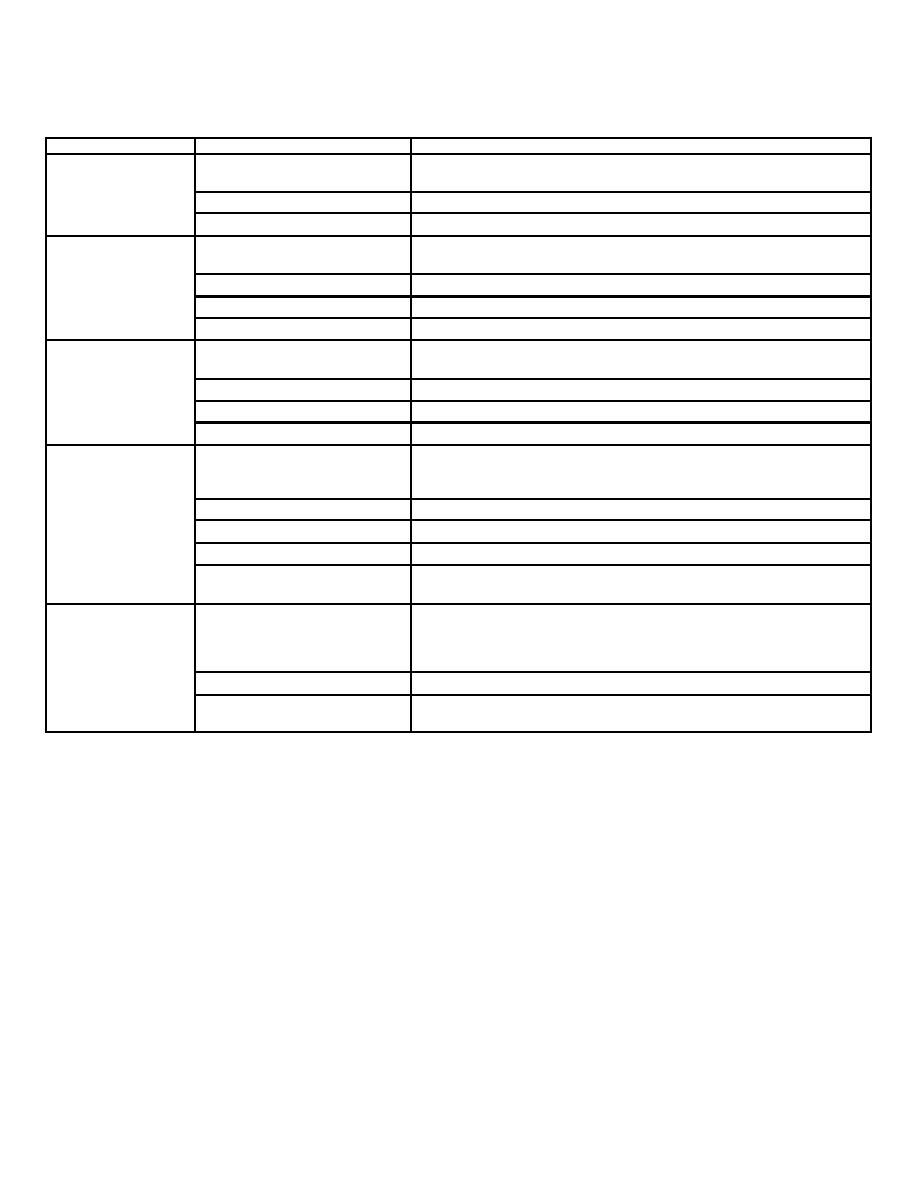

TM 55-4920-335-14

TABLE VI. Troubleshooting (Cont)

Trouble

Probable Cause

Remedy

Restricted flow in inlet line.

Clean inlet strainer. Remove water and sludge from fuel tank.

Low engine fuel

pressure.

Defective fuel pump.

Replace fuel pump.

Loose fuel line connections.

Tighten all connections between tank and pump.

Defective carburetor.

Replace carburetor.

Excessive fuel

consumption.

Fuel leaks.

Check tank, lines and all fittings.

Dirty air cleaner.

Clean mesh air cleaner element.

Choke partially closed.

Open choke.

Faulty regulator.

Replace regulator.

Battery needs

frequent recharging.

Electrolyte level not maintained.

Keep correct level by daily inspection.

Generator output inadequate.

Check generator for specified output, replace if necessary.

Loose or broken fan belt.

Adjust belt tension or replace belt.

Pump not primed.

Failure of hydraulic

Open line from compensator shutoff valve to compensator on pump.

pump.

Open compensator shut-off valve and operate pump until oil is free of air.

Stop engine, reconnect lines.

Pump cannot be bled.

Replace clogged filter element.

Sheared drive shaft on pump.

Replace pump.

Shaft seal leakage of pump.

Remove pump for overhaul.

Refill hydraulic reservoir.

Seizure due to inadequate oil

supply.

High pressure relief

Control cone not seating

Remove control knob seal piston, compression spring and cone. Inspect

valve chattering.

properly. Foreign material

cone for defects, replace if necessary. If trouble persists, remove valve

for overhaul.

lodged between control cone and

seat.

Valve improperly adjusted.

Adjust valve to proper setting for specific aircraft system.

Relief valve spool remaining

Remove valve for overhaul.

inoperative.

5-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |