|

| |

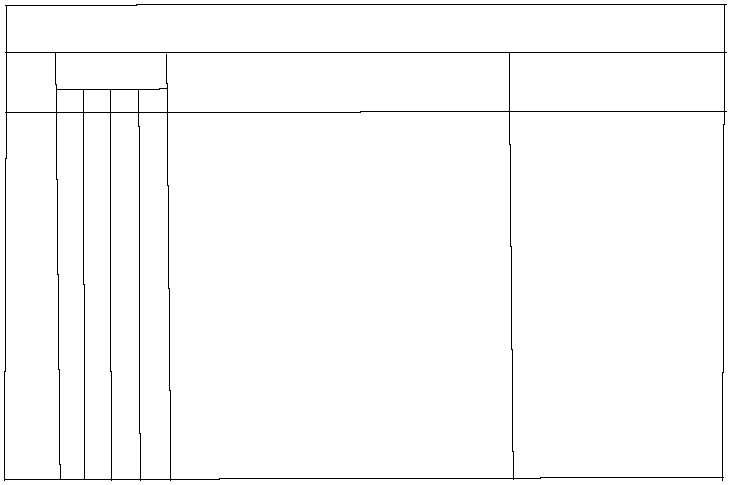

TM 1-1730-231-13&P

Table 3-1. Inspection Requirements (Continued)

INTERVAL DEFINITIONS

D - DAILY Q - QUARTERLY S - SEMI-ANNUALLY A - ANNUALLY

ITEM

INTERVAL

ITEM TO BE INSPECTED/PROCEDURE:

EQUIPMENT IS NOT

NO.

CHECK FOR AND HAVE REPAIRED,

READY/AVAILABLE IF:

D

Q

S

A

FILLED, OR ADJUSTED AS NEEDED

TIRES/WHEELS AND FILTER

18

x

Inspect tires for deep cuts,

excessive wear, and embedded

foreign matter.

19

x

Inspect for loose wheel

mounting bolts.

20

x

Inspect wheel bearings for

lubrication fittings and

grease.

21

x

Inspect filter indicator for

Filter is

dirty or clogged indication.

clogged.

ELECTRICAL CABLES/WIRES

22

x

Check electrical cables and

wires for breaks, worn insula-

tion, and loose connections.

3-10.

Lubrication. Grease cart wheel bearings with MIL-G-10924 grease, using grease gun, and oil door and control

panel cover hinges with VV-L-800 oil using oil can.

SECTION IV. TROUBLESHOOTING

3-11.

Troubleshooting. In the event that operation of the cart becomes faulty or erratic, refer to the troubleshooting

procedure, Table 3-2, to aid in isolating and correcting troubles.

Table 3-2. Troubleshooting Procedure

Is electrical power

NO

Check power cable is connected

available?

to either aircraft source or to

batteries. Check power cable

YES

and connectors (Para. 3-36).

3-5

|