|

| |

TM 9-5130-338-12&P

4-19. INSPECTION-ACCEPTANCE/REJECTION CRITERIA-Continued.

3.

Pulled or distorted threads

4.

Rusted or corroded

f.

Special. Clean all parts of hydraulic impact wrench in accordance with paragraph 4-9. Dry with cloth (Appx. C,

item 5). Inspect parts for evidence of excessive wear or damage. Carefully examine surfaces of parts that are

subject to wear caused by mating with, or rubbing against, adjacent surfaces. If a severe wear condition is found

on a part, its mating part should be closely examined. If any abnormal condition is noted in mating part, both

parts should be replaced during assembly. If damage is evident on any part, cause of damage should be

determined and corrected. Special inspection procedures are as follows:

1.

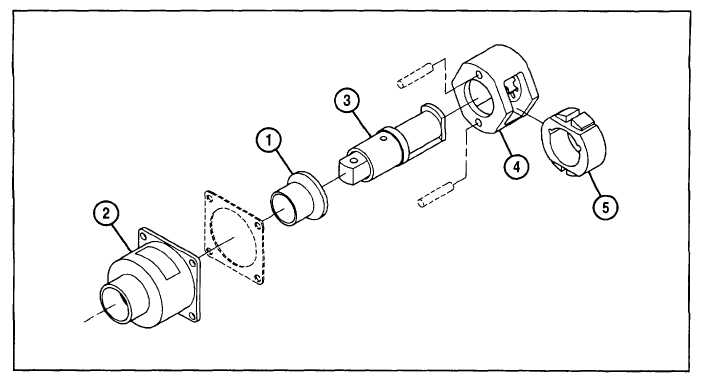

Impact Head Assembly Components.

(a)

Bushing (1). Visually inspect for following:

(1)

Foreign material imbedded in bearing face

(2)

Scoring

(3)

Flaking

If any of above conditions exist, bushing must be replaced.

(b)

Inspect hammer case assembly (2), anvil (3), hammer frame assembly (4), and hammer (5) as

described in f above.

4-20

|