|

|||

|

|

|||

|

Page Title:

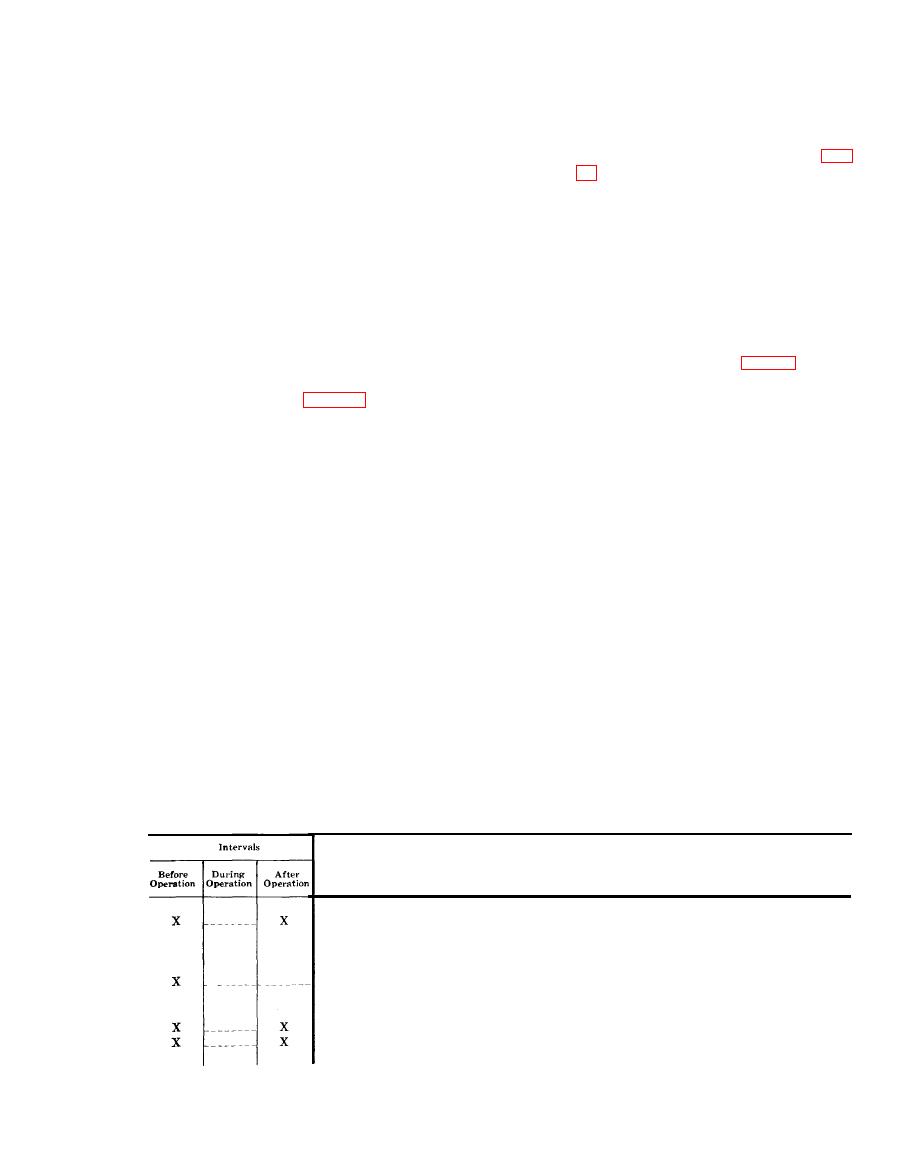

Section III. PREVENTIVE MAINTENANCE SERVICES |

|

||

| ||||||||||

|

|

f. Air Cleaner.

(2) Remove the cartridge from inside the

filter and discard.

(1) Remove the air intake cap (10, fig.

(3) Wipe the inside of the filter with a

lint-free cloth making' sure all dirt and

Loosen the thumbscrew (15) and re-

(2)

sludge are removed.

move the oil cup (17) from the air

cleaner assembly (14).

(4)

Insert a new cartridge in the filter

body. Be sure the correct end of the

Discard the oil in the oil cup. Wash

(3)

cartridge is up.

the oil cup and air intake in an ap-

p r o v e d cleaning solvent and dry

Install a new gasket in the cover (26).

(5)

thoroughly.

Place the cover on the oil filter (24)

and tighten the bolt (27).

Fill the oil cup to the level mark with

(4)

clean oil of the proper grade. Refer

Add one quart of oil to the engine

(6)

to the lubrication chart table 1. Install

crankcase to compensate for oil lost in

the oil cup on the air cleaner body and

servicing the oil filter. Refer to lubri-

tighten the thumbscrew (15) to se-

cation chart table 1 for the proper

cure.

grade oil.

Install the air intake cap on the top

(5)

Operate the unit immediately after

(7)

of the air cleaner assembly.

servicing (d above).

Section Ill. PREVENTIVE MAINTENANCE SERVICES

tinued. After-operation services will be per-

53. General

formed by the operator after every operating

To insure that the equipment is ready for

period. After-operation services will be per-

operation at all times, it must be inspected

formed at intervals based on the normal opera-

systematically before operation, during opera-

tions of the equipment. Reduce interval to com-

tion, and after operation, so that defects may be

pensate for abnormal conditions. Defects or

discovered and corrected before they result in

unsatisfactory operating characteristics beyond

serious damage or failure. The necessary pre-

the scope of the operator to correct must be re-

ventive maintenance services will be performed

ported at the earliest opportunity to organiza-

before operation. Defects discovered during

tional maintenance. Responsibility for perform-

operation of the unit will be noted for future

ance of preventive maintenance services rests

correction, to be made as soon as operation has

not only with the operator, but with the entire

ceased. Stop operation immediately if a defi-

chain of command from section chief to com-

ciency is noticed during operation which would

manding officer (AR 7505).

damage the equipment if operation were con-

54. Operator's Daily Services

Procedures

Visual inspection. Make a general inspection of the entire unit for obvious deficiencies,

such as oil or fuel leaks, loose or missing bolts, nuts, screws, loose connections, broken

wires, and any damage that may have occurred since the equipment was last

operated. Correct or report any deficiencies to field maintenance.

Tampering. Inspect the test stand for evidence of tampering or damage. Do not operate

the unit until all defects are corrected or reported to direct and general support

maintenance.

Fuel. Check the fuel supply. See that the fuel tank is full.

Leaks. Inspect for leaks, paying particular attention to the fuel line and connections.

Correct all deficiencies noticed or report to direct and general support maintenance.

AGO 5742A

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |