|

| |

TM9-6115-667-13&P

heard. The bearing housing contains two seal check

balls which are retained by hex socket type plugs. The

hex socket plugs can be viewed from the outside of the

bearing housing (9). The check balls and hex socket

plugs are not field serviceable items and therefore, are

not shown in figure 3. The purpose of the seal balls is to

prevent oil pressure from damaging the drive shaft seals

in the event hydraulic system supply and return hoses

are connected incorrectly (see CONNECT HOSES on

page 7 of this manual). If the balls do not rattle, this may

mean they are jammed because of fluid contaminants.

Replace the bearing housing (9).

Drive Shaft (11, figure 3) and Idler Shaft (6, figure 3)

Shaft diameters at bearing and seal locations must be

smooth. Grooves, roughness or a reduced diameter

indicate fluid contamination or damaged bushings. Grit

particles may have been imbedded in the bushings

grinding into the hardened shaft. If abnormal shaft wear

as above occurs (more than normal polishing), replace

both the shaft and associated bushings.

Also

check

the

hydraulic

system

for

excess

contamination in the fluid and for filter condition.

Operating conditions may require changing from a 25-

micron filter to an oversized 10-micron filter.

RE-ASSEMBLY

• Be sure to replace all exposed seals with new parts.

• Apply clean grease or o-ring lubricant to all parts during

reassembly.

1. Carefully install the quad ring (18) into the

groove on the inside of the seal gland (16). Carefully

install the o-ring (17) onto the smaller outside diameter of

the seal gland (16) and install the seal gland into the

bore of the bearing housing (9). Replace the retaining

ring (15).

2. To replace the bearing (13) on the drive shaft

(11), support the bearing inner race and press the drive

shaft through the bearing inner race. Install the retaining

ring (14) next to the bearing on the shaft.

3. Install the bushings (3) into the housings using a

typical bearing pusher. Make sure the bushing is flush

with the surface of the bearing housing. A protruding

bushing will bind the gears.

4. Place the bearing housing (9) on a smooth clean

arbor press surface (protected from damage) TM96115-

667-13&P with the large bearing bore facing up.

Position the piece so a clearance hole exists for the

insertion of the drive shaft (11).

5. Apply grease to the drive shaft (11) and keyway;

then insert it through the seal gland (16). Using a

bearing pusher, or a sleeve/socket with a diameter of the

bearing, press the bearing and drive shaft assembly into

place. Press only on the outer race. Install the bearing

retaining ring (10).

6. Install the needle roller (12) in the keyway of the

drive shaft. Use grease to keep the needle roller in

place. Slide the drive gear (8) over the needle roller and

drive shaft. Install the idler shaft (6) and idler gear (7).

7. Apply grease to the face seal o-ring groove; then

install the o-ring (4).

8. Note the screw hole pattern on the bearing

housing (9) and the gear housing assembly (1). They

will only assemble one way. With all parts aligned,

carefully slide the gear housing assembly over the gears

until it contacts the bearing housing.

9. Turn the drive shaft (11) manually to check for

free rotation. Install the eight 1/4-20 x 2-1/4 inch/ 57 mm

long capscrews (5) and tighten to 100-120 in-lbs torque.

Recheck rotation.

10. Connect the Hyrevz motor to a hydraulic power

source and check for smooth running.

Note: Make sure the hydraulic power source is running

at the lowest gpm/lpm rate it can while still producing full

pressure.

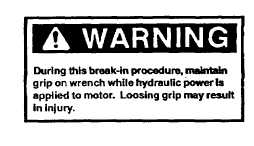

11. Hyrevz motors will sometimes be tight and require

“break-in”. Accomplish this by turning the

11

|