|

|||

|

|

|||

|

Page Title:

Chapter 2. lNSTALLATION AND OPERATING INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 55-1730-202-14

lNSTALLATION AND OPERATING INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF EQUIPMENT

CAUTION

Exercise care in removal of the crate

top to prevent damaging the equipment

with the prying tool.

a. Pry the top from the sides of the crate and

remove the jack and its allied parts from the

crate.

b. Remove the pressure-sensitive tape from all

sealed openings. Clean preservatives from all

unpainted metal surfaces with cleaning solvent

(Federal Specification P-D-680).

7. INSPECTION OF NEW EQUIPMENT.

a. Peferom the before-operating services de-

scribed in paragraph 26.

b. Make a thorough visual inspection of the

equipment for cracks, breaks, distortion, and

loose or missing parts.

c. Inspect all parts and assemblies for correct

and secure mountings.

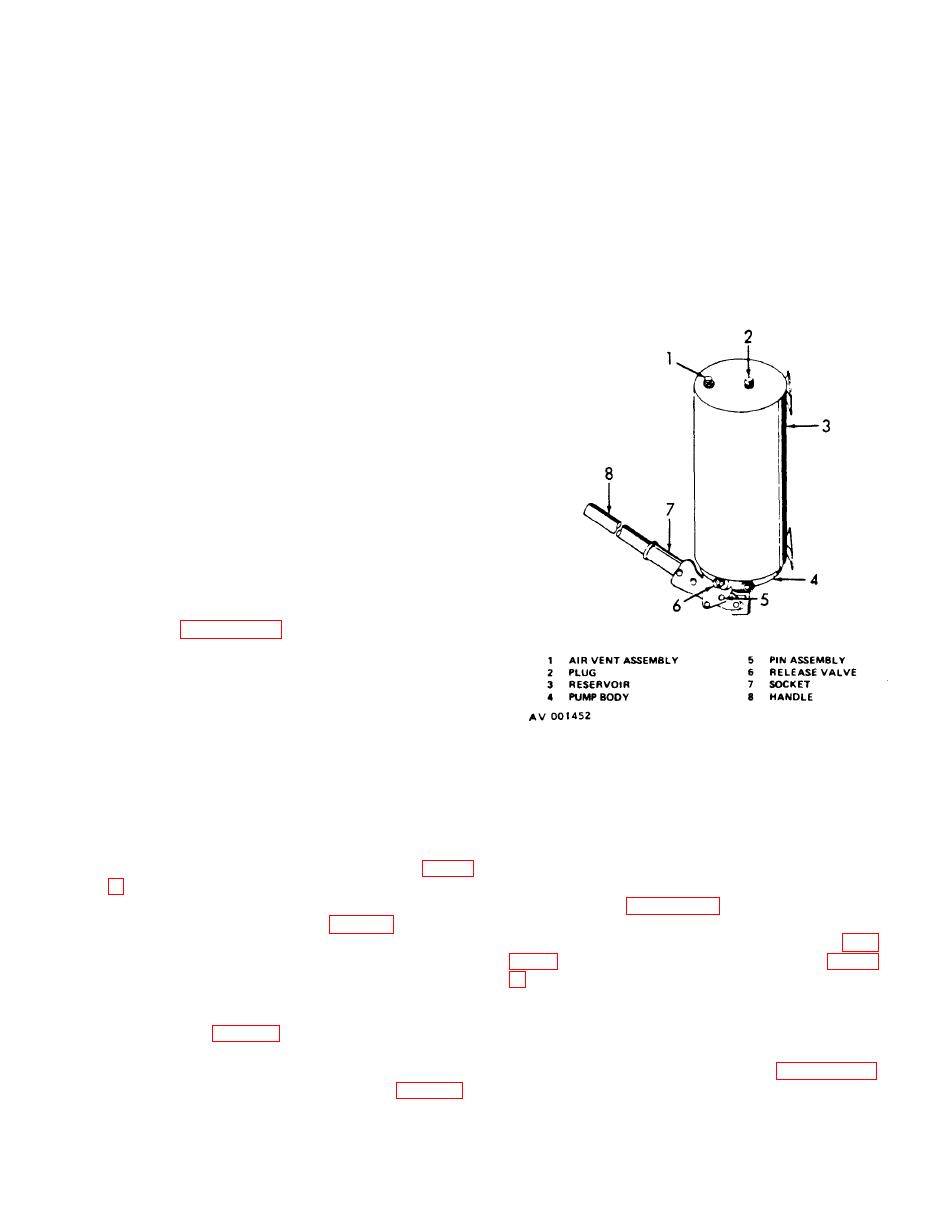

Figure 2. Controls.

d. Correct all deficiencies or report them to the

p r o p e r authority.

hose held above the attached end, actuate the

pump to fill the hose with oil. Attach the hose

8. SERVICING NEW EQUIPMENT.

to the cylinder and ram assembly.

a. Pump Assembly.

Inspect a used tripod hydraulic jack, following

the clamp assembly (14).

instructions in paragraph 7. Pay particular atten-

tion to the components which may be worr:

top of the pump assembly. Fill with hydraulic

through use, such as the extension screw (2, fig-

oil (OH) within one inch of the filler hole.

b. Cylinder and Ram Assembly.

(1) Lay the jack on its side so the inlet

authority.

opening at the bottom of the cylinder and ram

10. SERVICING USED EQUIPMENT.

assembly (5, figure 1) is up. Pour hydraulic oil

into the opening, expelling all air from the

Service a used tripod hydraulic jack in accord-

cylinder.

ance with instructions contained in paragraph 8.

Pay particular attention to filling the cylinder

(2) Attach the hose assembly (6, figure 5)

to the pump assembly. With the free end of the

and ram assembly with oil.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |