|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-1730-202-14

c.

Cleaning

and

Inspection.

(1)

Clean

all

parts

with

cleaning

solvent

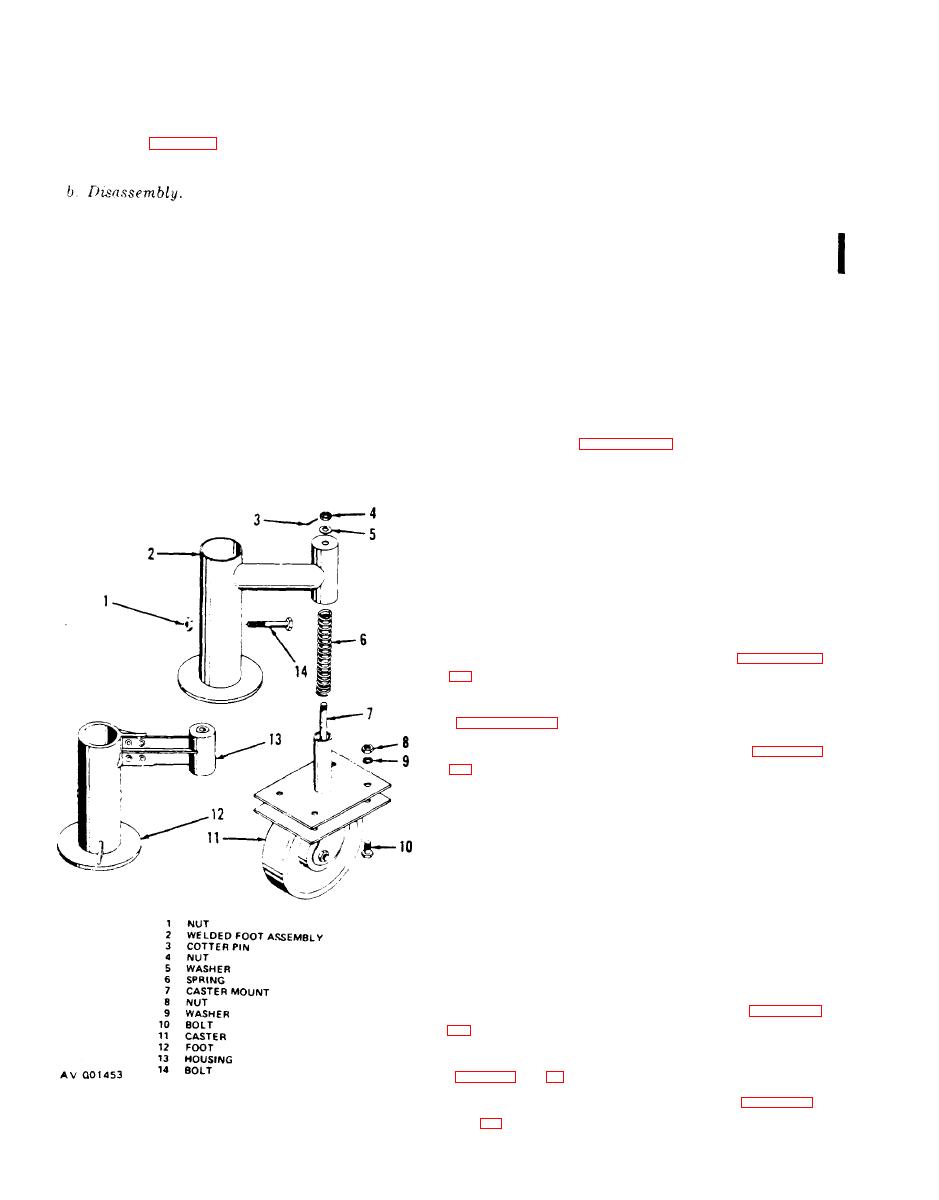

a. Removal. Lay the jack on its side. Remove

(Federal

Specification

P-D-680)

and

dry

thor-

the

nuts

(1,

and

bolts

(14)

and

pull

oughly.

the foot assemblies off the leg extensions.

(2)

Inspect

all

parts

for

damage

and

corro-

sion.

Check

the

casters

to

determine

they

rotate

and

swivel

freely.

Replace

all

defective

parts

(1)

Remove

the

cotter

pin

(3),

nuts

(4),

Retouch or repaint damaged painted surfaces as

and washer (5) that secure the caster mount (7)

required (Federal Specification TT-E-489G, color

13538, Federal Standard 595A).

to the welded foot assembly (2) and remove the

d. Reassembly.

mount with attached caster (11) and spring (6)

(1)

Position

the

housing

(13)

on

the

foot

from the foot assembly.

(12 ) and secure with the four bolts, lockwasher,

(2) Remove the four nuts (8), four washers

a n d nuts.

(9), and four bolts (10) that secure the caster

(2) Secure the caster (11) to

the caster

to the mount and remove the caster.

mount (7) with the four bolts (10),

four wash-

(3) Disassemble the cast foot assembly by

ers

(9),

and

four

nuts

(8).

removing the four nuts, Iockwashers, and bolts

(3)

Lubricate

the

caster

and

stem

of

the

that secure the foot (12) to the housing.

caster

mount

Place

the

spring

(6) and the caster mount with attached caster in

the

welded

foot

assembly

(2)

and

install

the

washer

(5),

nut

(4),

and

cotter

pin

(3).

e.

Installation.

Push

the

foot

assemblies

on

the leg extensions and secure with the bolts (14)

and nuts (1).

43. TRIPOD ASSEMBLY.

a. R e m o v a l .

(1)

Remove t h e pump

assembly

(2) Remove t h e cylinder and ram assembly

(3)

Remove the foot assemblies (paragraph

b. Cleaning and Inspection.

(1) Clean the tripod assembly with clean-

ing solvent (Federal Specification P-D-680) and

dry thoroughly,

(2) Inspect the tripod assembly for cracks,

breaks,

and

distortion.

Replace

a

defective

or

damaged

part.

(3) Retouch or

repaint

damaged

painted

surfaces as required.

c.

Installation.

(1)

Install

the foot

assemblies

(2)

Install

the cylinder

and

ram

assembly

(3)

Install

the

pump

assembly

graph 39) .

Change 3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |