|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

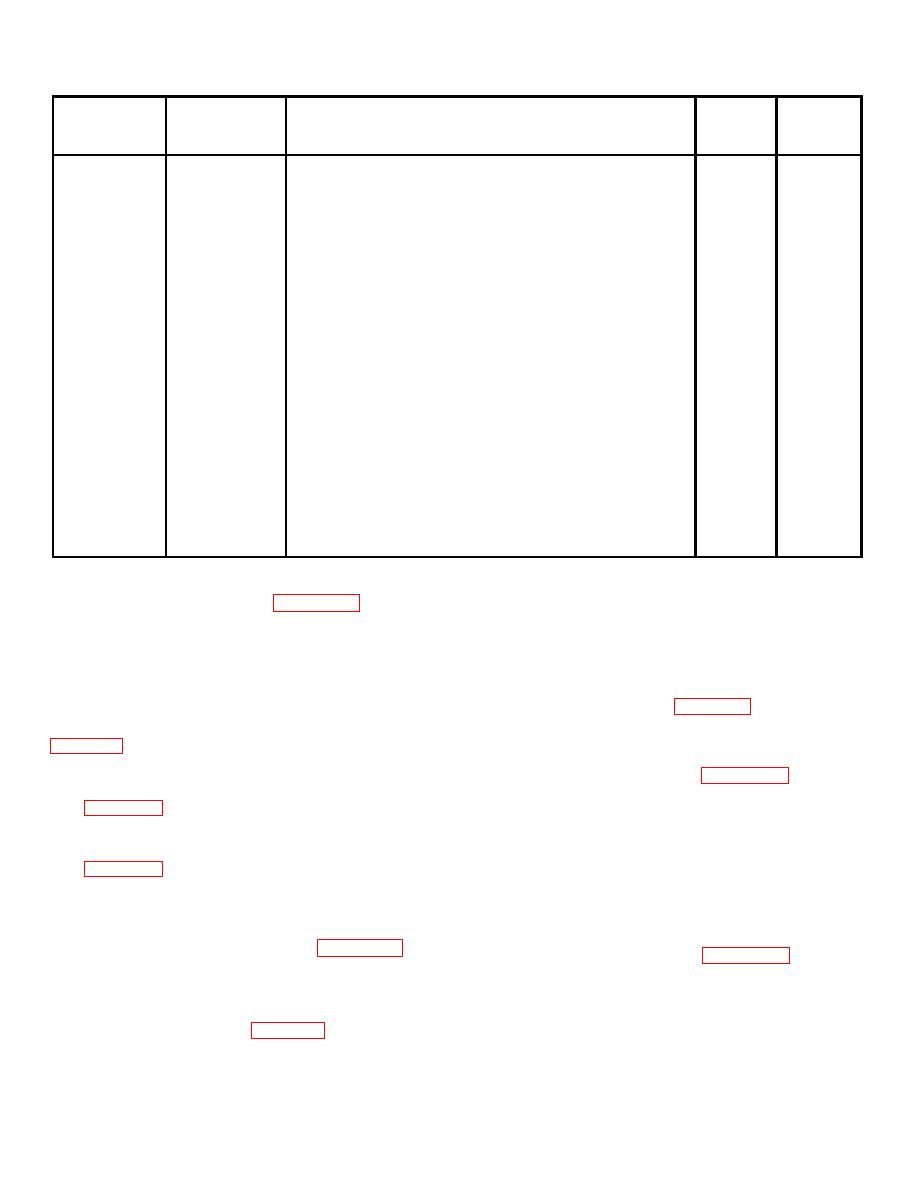

TM 55-1730-208-13

FIGURE &

QTY

USABLE

INDEX

PART

DESCRIPTION

PER

ON

NO.

NO.

1234567

ASSY

CODE

3-5-

TRIPOD ASSEMBLY ......................................................

1

-1

50B25235

.

LEG, Jack extension.................................................

12

-2

.

BOLT .......................................................................

12

-3

MS21044N8

.

NUT, Self-locking hexagon .......................................

12

(RPLS P/N AN365-820 leg)

-4

50B25197

.

LEG (80049).............................................................

3

-5

50B25213

.

BRACE, Jack, Tripod, No. 1 .....................................

6

-6

50B25211

.

BRACE, Jack, Tripod, No. 2 .....................................

6

-7

5'0B25218

.

BAR, Tension, Tripod jack ........................................

1

-8

AN8-6A

.

BOLT, Machine ........................................................

3

-9

MS35338-48

.

WASH, Lock.............................................................

3

-10

50C25244

.

WEB, Brace, Tripod Jack .........................................

1

-11

50B25216

.

BRACE, Jack, Tripod, No. 3 .....................................

6

-12

50B25214

.

BRACE, Jack, Tripod, No. 4 .....................................

6

-13

.

BOLT .......................................................................

12

-14

.

NUT .........................................................................

12

-15

50B25145

.

BRACE, Jack, Tripod, No. 5 .....................................

6

-16

50A25203

.

CONNECTING LINK, Rigged ...................................

6

-17

50A25248

.

STUD, Jack, Tripod ..................................................

3

-18

MS21044N8

NUT, Self-Locking, Hexagon ..........................................

6

(RPLS P/N AN365-820)

Clean cylinder and ram assembly (figure 33) with

3-33. Pump Assembly.

dry cleaning solvent (item 1, table 1-2) by spray or brush

Clean pump assembly (figure 3-2) with dry

application. Clean hose assembly (39) by flushing with

cleaning solvent (item 1, table i-2) by immersion or

dry cleaning solvent (item 1, table 1-2). Dry thoroughly

brush application.

Dry thoroughly with filtered,

with filtered, compressed air.

compressed air. Remove screen (32) from intake port

of pump body (38). clean with filtered, compressed air,

3-35. Foot Assemblies.

and insert in intake port.

Clean foot assembly (figure 3-4) by immersion in

dry cleaning solvent (item 1, table 1-2).

a. Air Vent Assembly. Clean air vent assembly (9,

3-36. Tripod Assembly.

table 1-2). Dry thoroughly with filtered, compressed air.

Clean tripod assembly (figure 3-5) with dry-

b. Safety Relief Valve. Clean safety relief valve

cleaning solvent (item 1, table 1-2) by spray or brush

(24, figure 3-2) by immersion in dry cleaning solvent

application.

(item 1, table 1). Dry with filtered, compressed air.

3-37. Inspection.

c. Safety Relief Valve. Clean safety relief valve

Inspect the clamp assembly, pump assembly,

(25, figure 3-2) by immersion in dry cleaning solvent

cylinder and ram assembly, foot assemblies, and tripod

(item 1, table 1-2).

Dry thoroughly with filtered,

assembly as follows:

compressed air.

d. Intake and Discharge Valves. Clean intake and

3-38. Clamp Assembly.

discharge valves (27 through 30, figure 3-2) by

for bent,

immersion in dry cleaning solvent (item 1, table 1-2).

cracked, or broken wings and distorted threads.

e. Release

Assembly

and

Associated

b. Inspect cam bolt (2) for shoulder wear and

Components. Clean release assembly and associated

distorted threads.

components (33 through 36, figure 3-2) by immersion in

c. Inspect front half clamp (6) and rear half clamp

dry cleaning solvent (item 1, table 1-2). Dry thoroughly

(7) for cracks, warpage, and excessive wear at pivot

with filtered, compressed air.

points.

3-34. Cylinder and Ram Assembly.

3-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |