|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

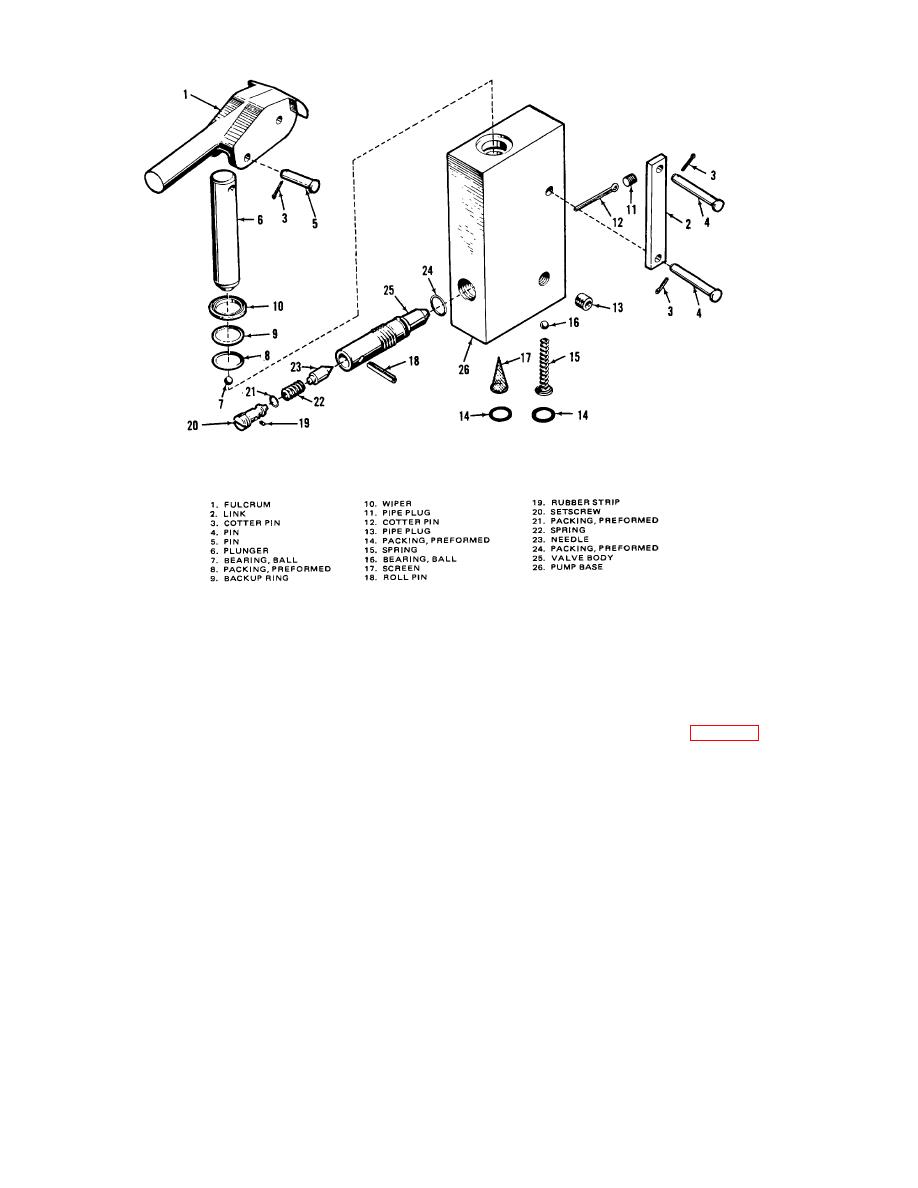

TM 9-1425-600-34-5-2

AV 006465

Figure 5. Pump Assembly.

(4) Needle tips (23) shall have a 10 finish and

(9) Balls (7) and (16) and ball seats for roughness.

valve seats shall have a 32 finish. Replace rough or

pitted parts.

(10) Screen for clogging or bending.

e. Reassembly.

d. Repair and Replacement.

(1) Place packing (24, figure 5) on body (25).

(1) Replace screen if it cannot be cleaned and

Place needle (23) and spring (22) in body. Install packing

restored to original shape.

(21) and rubber strip (19) on screw (20); thread screw into

(2) Replaced weak or damaged springs.

body. Turn approximately 4 turns after contacting spring.

(3) Replace damaged balls and clean damaged

Install pin (18) and thread assembly into base.

seats. Reset balls by tapping a new ball into the seat with

a brass drift to form a ring approximately 1/64th of an

inch. Discard the ball used for seating

11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |