|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

T.O. 35A2-2-39-11

T M 55-1730-221-12

Part and

adjustments and tests outlined in paragraphs 3-11 and

Index No.

3 - 1 5 through 3-17, and shall consist of the following:

Description

a. A hydraulic or pneumatic actuating cylinder with

0.496

Minor

diameter

---

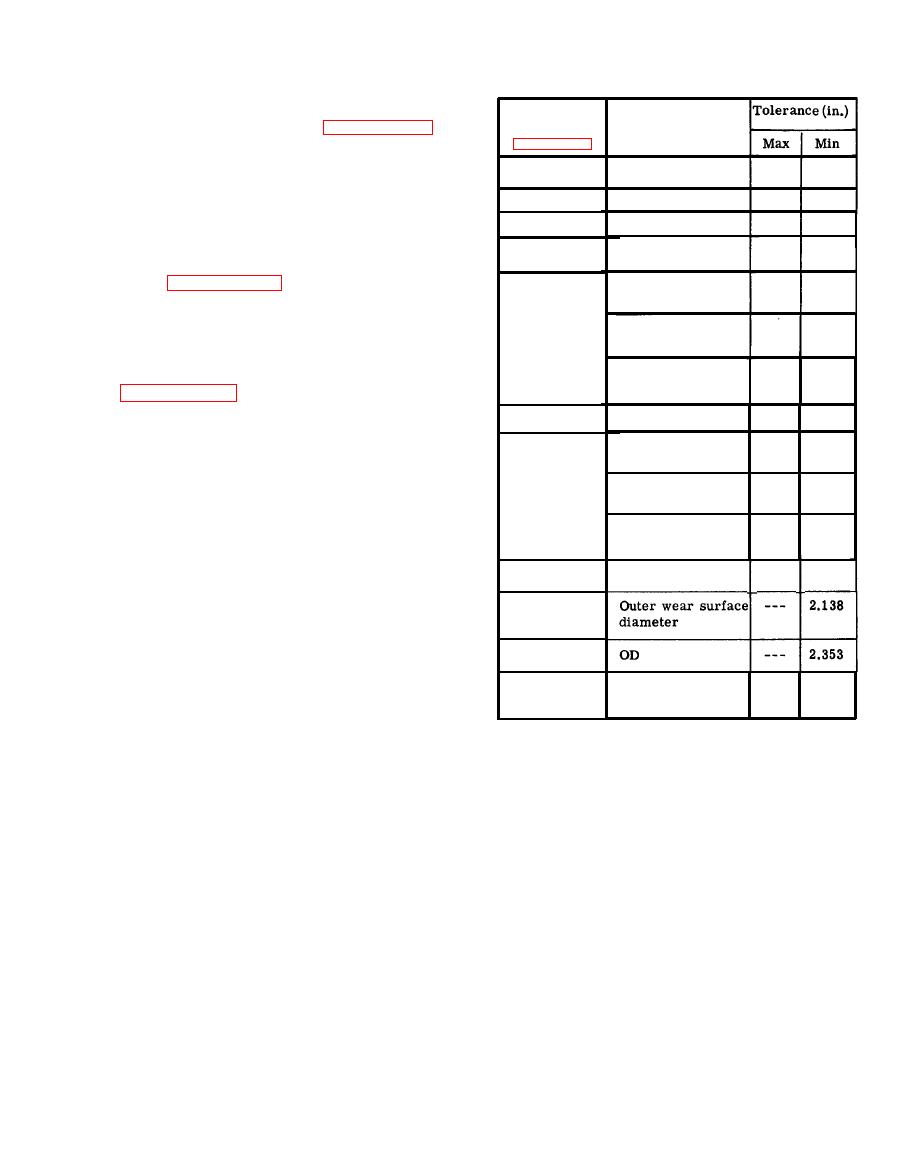

Piston (8)

a 12 ton maximum load capacity and a source of

0.507

---

ID

Nut (9)

hydraulic or air pressure equipped with an adjustable

relief valve to operate the cylinder.

0.502

---

Minor ID

B o d y (12)

b. A platform type weighing scale calibrated to

3.496

---

ID

Bushing (31)

24,000 pounds for load measurement. Mount cylinder

(refer to paragraph 3-4a) in a stationary, vertical

Outer wear surfaces

---

3.487

Ram (33)

position, and place scale directly beneath, so that

jack can be positioned between cylinder and scale.

2.991

---

Major inner wear

T h e s e components shall be positioned so that thirteen-

surface diameter

inch compression of cylinder ram is permitted.

2.793

---

Minor inner wear

surface diameter

to paragraph 3-14). Operate handle (1) to lift rams

( 3 3 , 39, 44) to contact cylinder. Adjust cylinder load-

---

3.667

Bearing (35)

OD

i n g to provide 20,000 pound (ten-ton) reading on scale.

With this load applied to jack, operate handle until

2.784

Outer wear surface

---

Ram (39)

the third-stage ram is partially extended. Visually

diameter

i n s p e c t jack for fluid leakage at pump packing nut (9),

2.364

---

Major inner wear

release valve (25), and rams. There shall be no fluid

surface diameter

leakage at any point. After test, open release valve

( 2 5 ) to lower jack.

2.147

---

Minor inner wear

surface diameter

to jack. Operate handle (1), applying force perpen-

---

2.980

OD

Bearing (41)

dicularly to axis of handle. Operating force required

during compression (downward) stroke shall be from

Ram (44)

75 to 80 pounds.

Bearing (46)

and operate handle (1) to raise rams against load.

Settling at this load shall not exceed 0.020 inch per

3.678

---

Cylinder wear

Base assem-

hour.

Perform this test twice with a 15-minute

b l y (56)

surface ID

interval between each test. Settling shall not exceed

0.005 inch at the end of each 15-minute period, a

t o t a l maximum of 0.010 inch at the end of the 30-min-

Open release valve (25) to lower jack

ute period.

Wear

Tolerance

after completion of tests.

*U.S. GOVERNMENT PRINTING OFFICE: 1993-342-421/80363

3-5 and 3-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |