|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-405-13&P

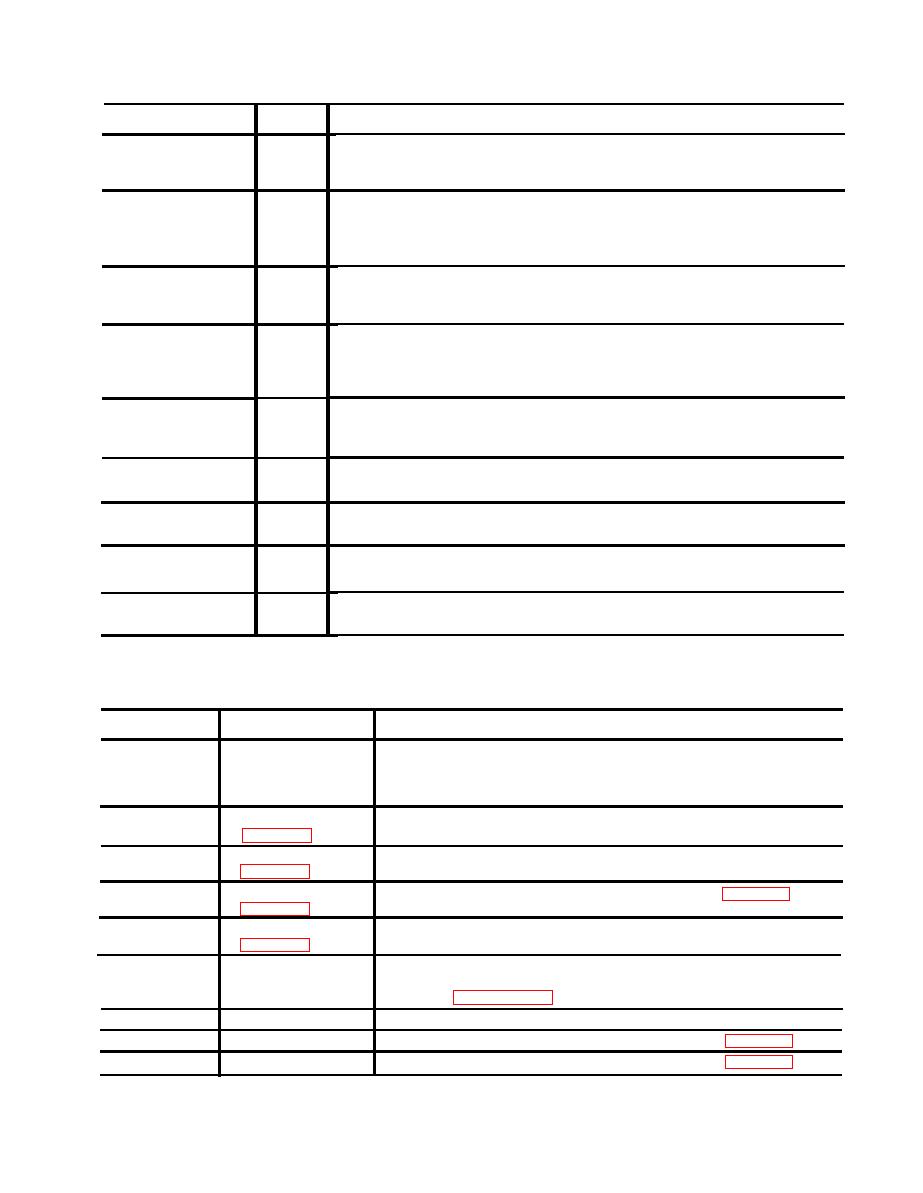

Table 3-3. Periodic Inspection Requirements - Continued

Item

Period

Requirements

100 hr

Wheels

Inspect for loose wheel mounting bolts. Inspect wheel bearings for

proper adjustment. Tighten loose wheel bolts and adjust wheel

bearings as necessary.

Axle

100 hr

Inspect axle assemblies for loose mounting hardware and improper

alignment. Inspect springs for cracks, breaks, and weakened con-

dition. Tighten all axle mounting hardware. Align front wheels as

necessary. Replace defective springs.

Brake assembly

Check to ensure that brakes operate properly. Inspect brake rods for

100 hr

loose mounting. Tighten all mounting hardware. Adjust brakes as

necessary.

Hydraulic pump

100 hr

Inspect hydraulic pump for loose mounting hardware and hydraulic con-

nections. Make sure that drive coupling is securely mounted and

properly aligned. Tighten all loose mounting hardware and hydraulic

connections. Replace defective drive coupling.

Hose assemblies

Inspect all hose assemblies for loose connections, cracks, breaks, and

100 hr

frayed or rotted fabric covering. Tighten loose connections. Replace

hose assembly, if it is otherwise defective.

Hydraulic tubing

100 hr

Inspect tubing for cracks, breaks, and distortion. Tighten all hydraulic

connections. Replace damaged or defective tubing or fittings.

High pressure filter

100 hr

Inspect filter assembly for dirty or clogged filter element that causes

excessive pressure drop. Replace dirty or clogged filter element.

assembly

Thermoswitch

Check thermoswitch for correct temperature response. Make sure it

100 hr

is tightly installed. Replace damaged or defective thermoswitch.

Low pressure filter

100 hr

Inspect filter assembly for dirty or clogged filter element that causes

excessive pressure drop. Replace dirty or clogged filter element.

assembly

Table 3-4. Daily Servicing

System

Component

Requirement

Open flip-cap vents along center line of battery top and check

Electrical

Battery

water level. If necessary, add clean, cold tap water through

flip-cap vent tubes to bring level of each cell to bottom of

tube.

Check connections; tighten if necessary.

Ignition wires

Check reservoir fluid level. Add hydraulic fluid, if necessary,

Hydraulic

Reservoir

to fill.

Engine

Using dip stick, check oil level. If low, add oil (table 3-5).

Fuel strainer

Check for foreign matter and water. Clean as needed.

Miscellaneous

Fuel tank

Check reading on FUEL LEVEL GAGE with IGNITION SWITCH

set to ON. Add gasoline as needed to bring reading to full

mark (paragraph 3-8).

Tires

Check tire pressure. Inflate to 60 PSI.

Check for free movement. Lubricate, if needed (table 3-5).

Access door hinges

Draw bar

Check for free movement. Lubricate, if needed (table 3-5).

,

3-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |