|

|||

|

|

|||

|

Page Title:

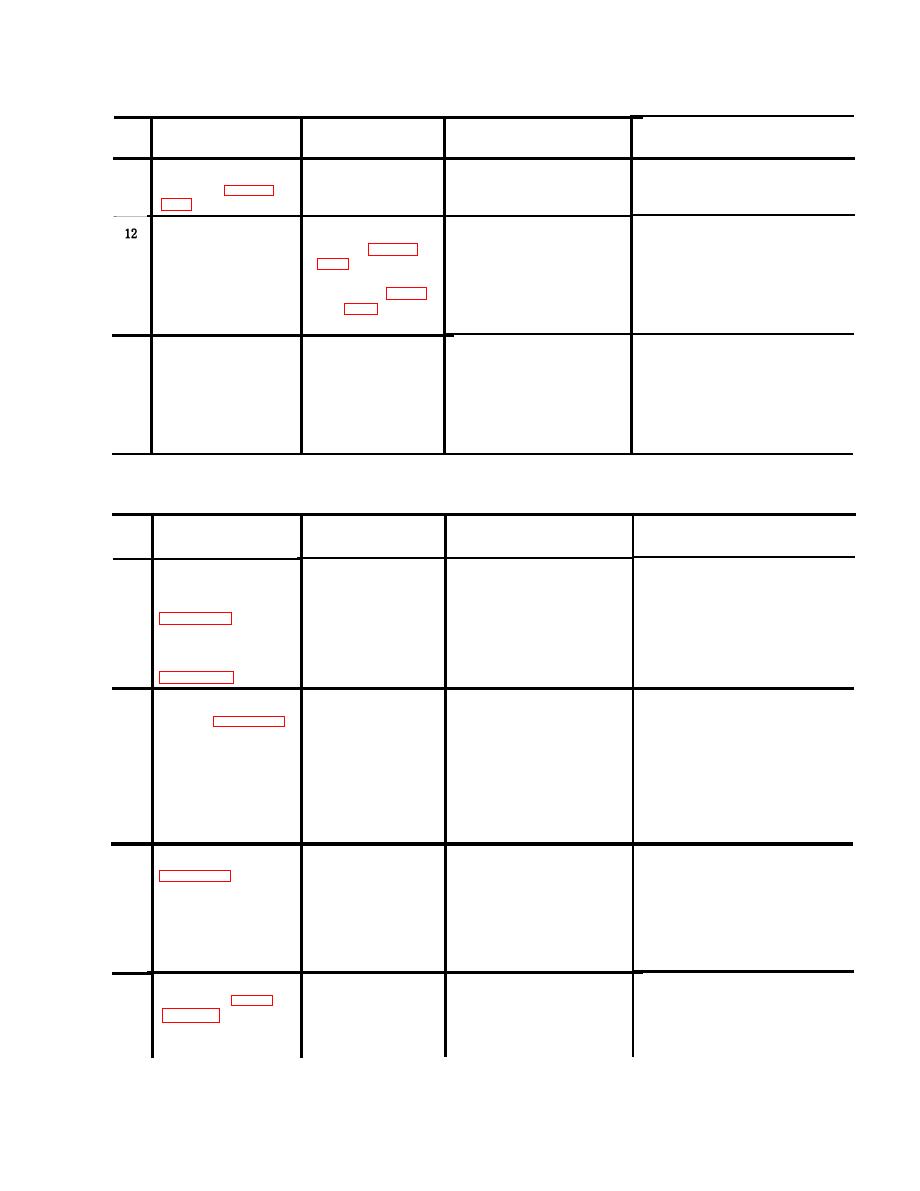

Table 4-2. Engine Start-up Performance Checks |

|

||

| ||||||||||

|

|

TM 55-4920-405-13&P

Table 4-1. Preliminary Performance Checks - Continued

Normal

Abnormal

Indication

Indication

Corrective

Action

Step

Action

RESERVOIR valve binds

Replace or repair as necessary.

11

Set RESERVOIR

RESERVOIR

or cannot be turned be-

valve (15, figure

valve turns

2-1) to IN.

freely.

cause it is defective.

Replace FUEL LEVEL gage.

FUEL LEVEL

FUEL LEVEL gage

Fill fuel tank.

does not indicate, or

gage (4, figure

2-1) reads full

indicates incorrectly.

when IGNITION

SWITCH (2, fig-

ure 2-2) is set to

ON.

Replace defective hose assem-

13

Hose assembly couplings

Hose assembly

Connect hose as-

blies or couplings.

couplings lock to

semblies between

cannot be attached to

test stand or system to

couplings on test

test stand and sys-

be tested because of de-

stand and system

tem that is to be

fective hose assemblies

to be tested.

tested.

or defective coupling on

test stand.

Table 4-2. Engine Start-up Performance Checks

Abnormal

Normal

Corrective

Action

Indication

Indication

Step

Action

Replace switch.

Positive action ground

Positive action

Make sure HIGH

1

switch does not pull out

ground switch

PRESS BYPASS

and engine will not start

pulls out and re-

VALVE control (19,

because switch or mag-

mains out.

figure 2-1) is set to

neto assembly is

OPEN. Pull out

defective.

positive action

ground switch (3,

a. Adjust, repair or replace.

CHOKE control cannot be

2

Pull CHOKE con-

CHOKE control

b . Adjust or replace.

pulled, can be pulled

operates freely.

trol (1, figure 2-2)

out only part way, or

to full out position,

binds. Probable cause:

then reset it to

about midway.

a . Defective carburetor.

b. Stuck cable to car-

buretor linkage, or

stuck carburetor

linkage.

a . Adjust or replace.

THROTTLE cannot be

3

Pull THROTTLE (3,

T H R O T T L E Op-

b . Repair or replace.

pulled out and locked.

erates freely

figure 2-2) to full

Probable cause:

out position, and

and can be locked.

reset to about one-

a. Jammed throttle

quarter out position.

cable or carburetor

Twist to right to

linkage.

lock, and release.

b . Defective carburetor.

Replace switch.

IGNITION SWITCH can-

IGNITION SWITCH

4

Set IGNITION

not be set to ON because

can be set to ON

SWITCH (2, fig-

it is defective.

and remains at

ure 2-2) to ON.

ON when

released.

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |