|

| |

TM9-6115-667-13&P

PREOPERATION

PROCEDURES

PREPARATION FOR INITIAL USE

The unit as shipped has no special unpacking or

assembly requirements prior to usage. Inspection of

ventilation holes to assure they do not contain packing

debris is all that is required. Otherwise, the unit may be

connected to a hydraulic source upon receipt.

ELECTRICAL BONDING

If required, ground bond the electrical load and hydraulic

motor generator at the ground lug mounted on the

alternator frame, lower right (as viewed from the front

SEE PAGE 3).

CHECK HYDRAULIC POWER SOURCE

1.

Using a calibrated flowmeter and pressure

gauge, check that the hydraulic power source develops a

flow of 7-9 gpm/26-34 Ipm at 10002000 psi/70-140 bar.

2.

Make certain the hydraulic power source is

equipped with a relief valve set to open at 2100 psi/145

bar maximum.

CONNECT HOSES

1.

Wipe all hose couplers with a clean lint-free cloth

before making connections.

2.

Connect the hoses from the hydraulic power

source to the hose couplers on the hydraulic motor

generator. It is a good practice to connect the return

hose first and disconnect it last to minimize or avoid

trapped pressure within the hydraulic motor on the

hydraulic motor generator.

3.

Observe flow indicators stamped on hose

couplers to be sure that oil will flow in the proper

direction. The female coupler is the inlet coupler.

Note: The pressure increase in uncoupled hoses left in

the sun may result in making them difficult to connect.

When possible, connect the free ends of operating hoses

together.

OPERATING

PROCEDURES

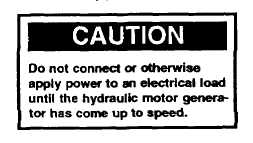

1.

Observe all safety precautions.

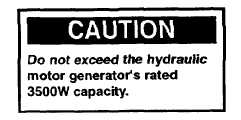

2.

Move the hydraulic circuit control on the Pioneer

Tool Outfit (PTO) to the ’ON’ position. As the hydraulic

motor generator comes up to speed, a maximum

electrical load of 3500W, single-phase 60-Hz alternating

current, at 120-volts becomes available.

3.

Connect the electrical loads.

Note: Output voltage is proportional to the RPM of the

hydraulic motor.

COLD WEATHER

OPERATION

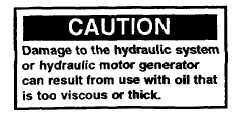

1.

Before using the hydraulic motor generator in

cold weather, preheat the hydraulic oil at low engine

speed. When using the normally recommended oils, oil

should be at or above 50F/1 0°C (400 ssu/82

centistokes) before use.

7

|