|

|||

|

|

|||

|

Page Title:

Section III. STRUCTURAL MEMBERS |

|

||

| ||||||||||

|

|

TM 55-1730-202-14

Figure 5-Continued.

Section Ill. STRUCTURAL MEMBERS

c. Cleaning, Inspection, and Repair.

(1) Clean all parts in cleaning solvent (Fed-

a. R e m o v a l . R e m o v e t h e c l a m p a s s e m b l y a n d

eral

Specification

P-D-680)

and

dry

thorough-

the

pump

assembly

39).

ly.

b. Disassembly.

(2)

Inspect

all

part

for

cracks,

breaks,

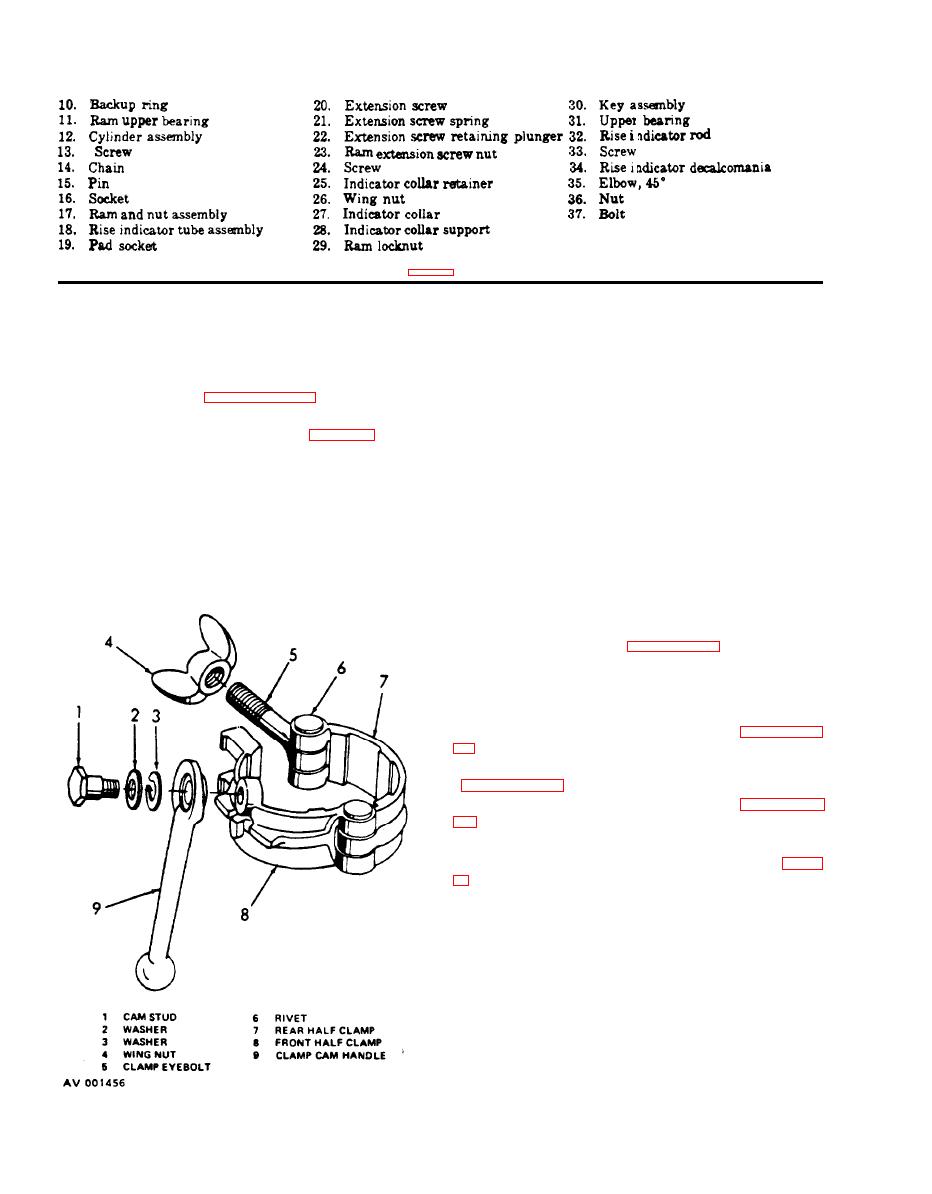

(1) Remove the cam stud (1, figure 6), two

distortion, and damaged threads. Remove nicks

washers (2 and 3), and the clamp cam (9) from

and

burrs

from

threads

and

straighten

distorted

the front half clamp (8).

parts. Replace any part damaged beyond repair.

(2)

Remove

the

wingnut

(4)

from

the

d. Reassembly.

clamp

eyebolt

(5).

Remove

the

two

rivets

(6)

(1) Install two new rivets (6) if removed

only

if

necessary

to

replace

defective

rear

half

during disassembly. Install

the

wingnut

(4)

on

clamp

(7),

front

half

clamp

(8),

or

clamp

eye-

the clamp eyebolt (5).

bolt (5).

(2) Install the clamp cam (9), two washers

(2

and 3), and the cam stud (1) on tie front

half

clamp

(8).

e. Installation. InstalI the pump assembly and

the clamp assembly (paragraph 39).

52. TRIPOD ASSEMBLY.

a.

Removal

(1) Remove the pump assembly (paragraph

(2)

Remove

the

cylinder

and

ram

assembly

(3)

Remove

the

foot

assemblies

b.

Disassembly.

(1) Remove the nine nuts (6 and 9, figure

six bolts (3), and three studs (10) that

secure the six no. 1 braces (2), six no. 2 braces

(5), six no. 3 braces (7), and six links (8) to

the leg extension (4) and remove the braces and

links.

(2) Pull the six leg extensions off the three

legs (1).

c.

Cleaning,

Inspection, and

Repair.

with

cleaning

solvent

(1) Clean all parts

P-D-680)

and

dry

(Federal Specification

thoroughly.

(2) Inspect the legs, leg

extensions,

braces,

and

links

for

cracks,

breaks,

and

distortion.

Figure 6. Clamp Assembly, Exploded View.

Straighten

bent

or

distorted

items

and

repair

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |