|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-1730-213-12

d. Correct all deficiencies or report them to the

20. INSPECTION OF USED EQUIPMENT.

proper authority.

a. Inspect used tripod hydraulic jack, following the

instructions in paragraph 25. Pay particular attention to

19. SERVICING NEW EQUIPMENT.

the components which may be worn, such as the

a. Pump assembly.

Remove filler and vent

extension screw (15, figure 2) and leg and caster

assembly (33, figure 2) from top of reservoir. Fill with

assembly (2, figure 3).

hydraulic fluid up to filler hole.

b. Correct or report all deficiencies to proper

b. Cylinder and ram assembly.

authority.

(1) Stand jack in an upright position. Pour

21. SERVICING USED EQUIPMENT.

hydraulic fluid into filler hole (33, figure 2) expelling all air

from reservoir and cylinder.

a. Service used tripod hydraulic jack in accordance

with instructions contained in paragraph 19.

(2) Actuate pump to fill cylinder assembly with

fluid, (figure 3).

b. Pay particular attention to filling the cylinder and

ram assembly with fluid.

(3) Use handle (1) for tool to move valve body

(11) to open or close position.

Section II. SPECIAL TOOLS AND EQUIPMENT

None required

Section III. LUBRICATION.

22. GENERAL

Table 1 is a lubrication chart. It is supplemented by the detailed lubrication information in paragraph 23.

23. DETAILED LUBRICATION INFORMATION.

a. Care of Lubricants. Replace covers on lubricant containers after use and store in a clean, dry place. Keep all

containers used for handling oil and fluid clean and ready for use.

b. Cleaning. Clean all lubrication fittings or points of application with a cloth dampened in cleaning solvent (Federal

Specification P-D-680) before applying lubricant.

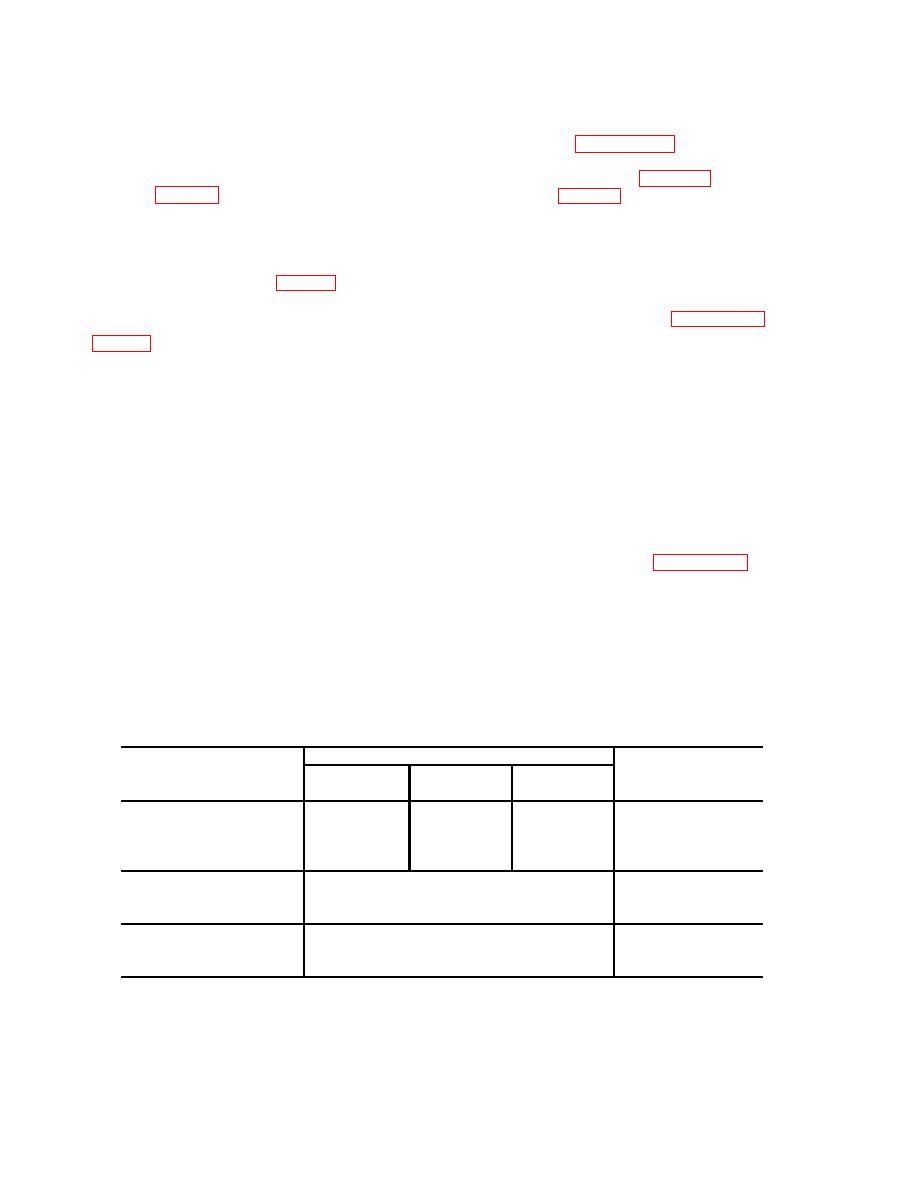

Table 1.

Lubrication Chart

EXPECTED TEMPERATURE

ABOVE

+32 to

F

-10 to

INTERVALS

+32

F

-10

F

-65

F

OH-HYDRAULIC

FLUID, Hydraulic

MIL-H-

MIL-H-

MIL-H-

500 hrs.

Cylinder and

5606

5606

5606

Pump Assembly

OE-OIL, Engine,

Extension screw

All temperatures

Monthly

Caster Wheels

GREASE,

MIL-G-10924

All temperatures

Monthly

Caster leg

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |