|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1425-600-34-5-2

normal operations of the equipment. Reduce interval to compensate for abnormal conditions. Defects or unsatisfactory

operating characteristics beyond the scope of the operator to correct must be reported at the earliest opportunity to

organizational maintenance. Responsibility for performance of preventive maintenance services rests not only with the

operator, but with the entire chain of command from section chief to commanding officer (AR 750-5).

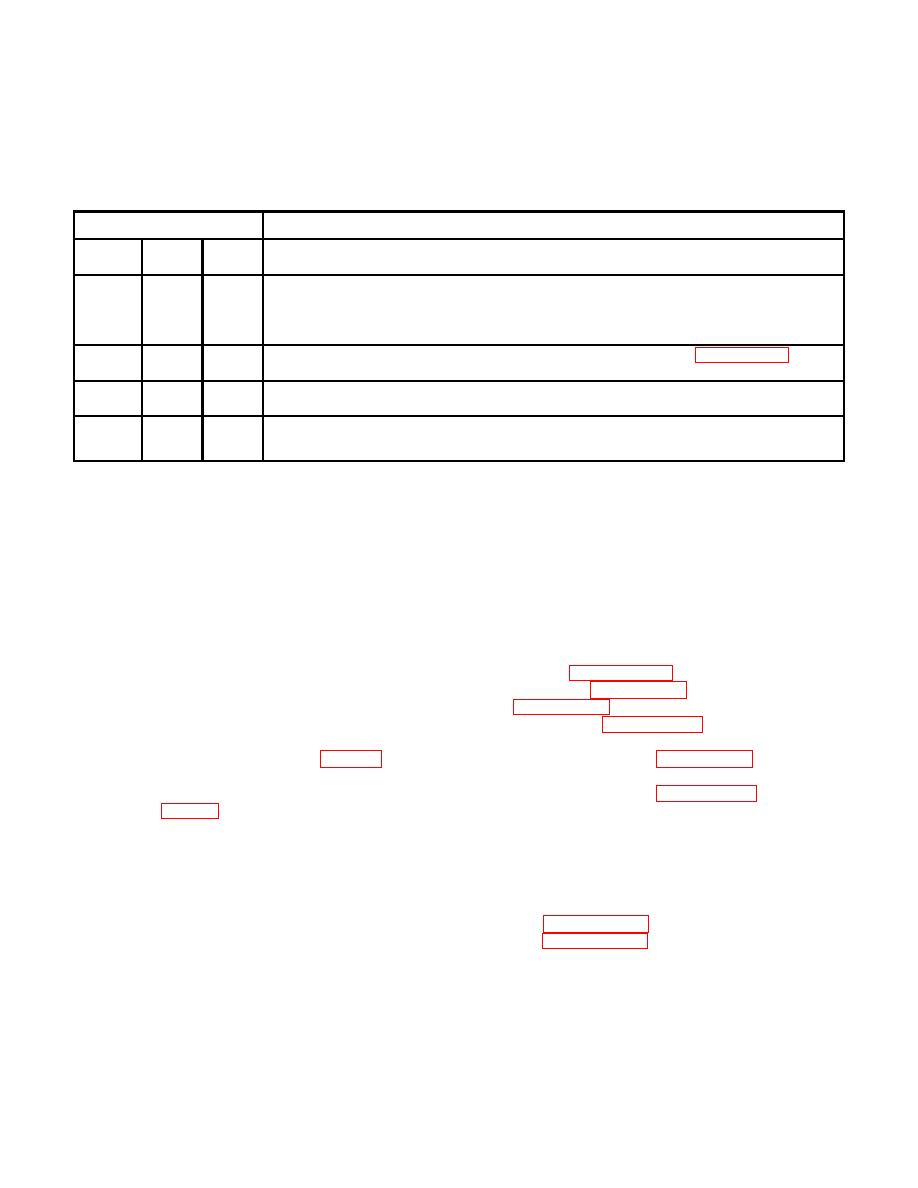

25. OPERATOR'S DAILY SERVICES.

INTERVALS

PROCEDURE

Before

During

After

operation

operation

operation

X

X

Visual inspection. Make general inspection of the entire jack for obvious defi-

ciencies, such as fluid leaks, loose or missing bolts, nuts, and any damage

that may have occurred since the equipment was last operated. Correct or

report any deficiencies to proper authority.

X

Fluid level. Check the fluid level in the reservoir and add fluid (paragraph 19)

as required.

X

X

X

Leaks. Check the pump assembly and the cylinder and ram assembly for signs

of leaks. Correct or report any deficiencies to proper authority.

X

X

Foot assemblies. Check the casters of the foot assemblies for free movement and

rotation of the wheels. Lubricate as required.

Section V. TROUBLESHOOTING

26. GENERAL.

The following paragraphs provide information useful in diagnosis and correction of deficiencies revealed upon

inspection, operation, or failure of the tripod hydraulic jack or any of its components. Each trouble symptom stated is

followed by a list of probable causes of the trouble. The possible remedy recommended is described opposite the

probable cause.

27. RAM WILL NOT RISE.

PROBABLE CAUSE

POSSIBLE REMEDY

Valve open .................................................................... Close valve (paragraph 13)

Fluid level low ................................................................ Refill with fluid (paragraph 19) and check for leaks

Air under the ram ........................................................... Bleed the system (paragraph 39)

Pump assembly screen clogged .................................... Report the malfunction to DS and GS maintenance

Intake ball bearing defective (7, figure 5) ....................... Replace pump assembly (paragraph 37) or report to

DS and GS maintenance

Discharge ball bearing defective .................................... Replace pump assembly (paragraph 37) or report to

(16, figure 5)

DS and GS maintenance

28. JACK WILL NOT RAISE CAPACITY LOAD.

PROBABLE CAUSE

POSSIBLE REMEDY

Pump assembly defective .............................................. Replace (paragraph 37)

Ram defective ............................................................... Replace (paragraph 38)

8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |