|

|||

|

|

|||

|

Page Title:

Section VII. NUMERICAL PARTS LISTING |

|

||

| ||||||||||

|

|

TM 9-1425-600-34-5-2

NOTE

For temperatures below -28.9 (29 ) use 3 parts of hydraulic fluid to 1 parts of

C

F

naphtha, specification TT-N95.

b. Check tightness of bolts.

c. Check operation of retractable casters.

d. Operate jack several times to bleed out trapped air. If air is still present, pump jack to full extension, remove

plunger, open the valve (11, figure 3). Lower jack as rapidly as possible without overflowing the pump. With fluid level

at the top of the reservoir, replace the plunger.

40. TEST AFTER OVERHAUL.

a. Install a pressure gage in either pipe plug opening in pump. The gage must be able to indicate 3500 psi.

b. Pump jack up to full extension. Continue operating pump until gage indicates 3182 psi. At this point the relief

valve should bypass fluid to the reservoir and prevent further increase. Raise or lower the setting to obtain correct

pressure. (See paragraph 37).

c. At this pressure, check all points for leaks. The most likely source of leaks are packings damaged during

assembly.

e. Remove gage and install plug.

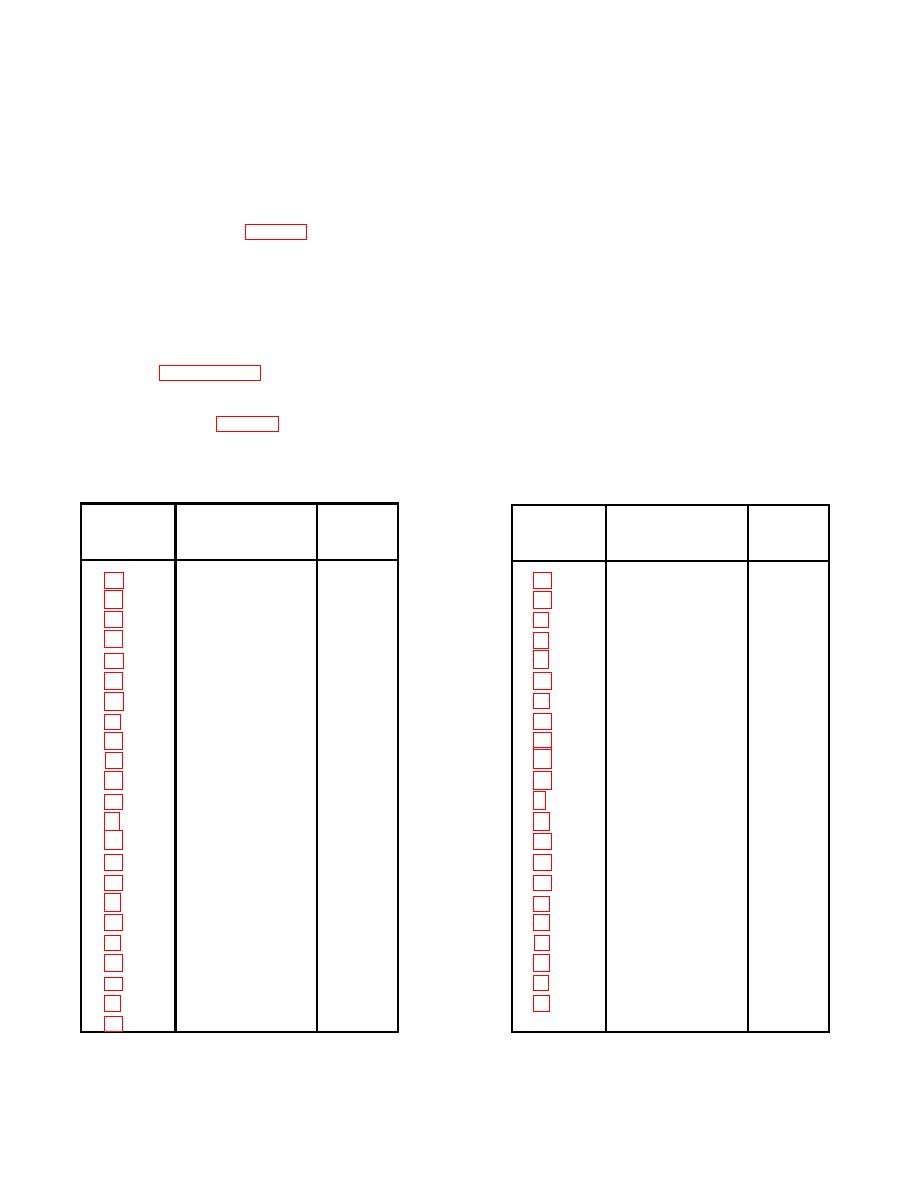

Section VII. NUMERICAL PARTS LISTING

FIG. AND

FIG. AND

INDEX NO.

PART NO.

FMC

INDEX NO.

PART NO.

FMC

AN380-4-6

88044

170-291

22598

AN395-65

88044

190-205

22598

2-18

AN6232-10

88044

5-25

20-118

22598

2-12

AN6232-13

88044

5-23

20-2-23

22598

AN6232-16

88044

2-21

200-32

22598

H5991-2

06004

210-78

22598

MS20392-10-87

96906

220-19

22598

MS20392-4C49

96906

230-23

22598

MS24665-302

96906

5-26

30-171

22598

2-13

MS28782-47

96906

2-29

34

00266

3-10

MS35338-51

96906

347

71447

5-13

MS49005-4

96906

2-4

40-79

22598

4-6

XSC-135

76665

2-25

50-188

22598

2-16

100-23

22598

5-18

59-048-250-100

22598

110-71

22598

2-23

60-236

22598

110-72

22598

65-6-14

22598

110-73

22598

65-6-6

22598

2-10

130-27

22598

70-81

22598

130-128

22598

2-11

70-94

22598

2-31

160-52

22598

79-95

22598

2-32

160-9-03

22598

2-17

80-149

22598

2-26

160-9-13

22598

2-15

90-43

22598

2-27

160-9-25

22598

14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |