|

|||

|

|

|||

|

Page Title:

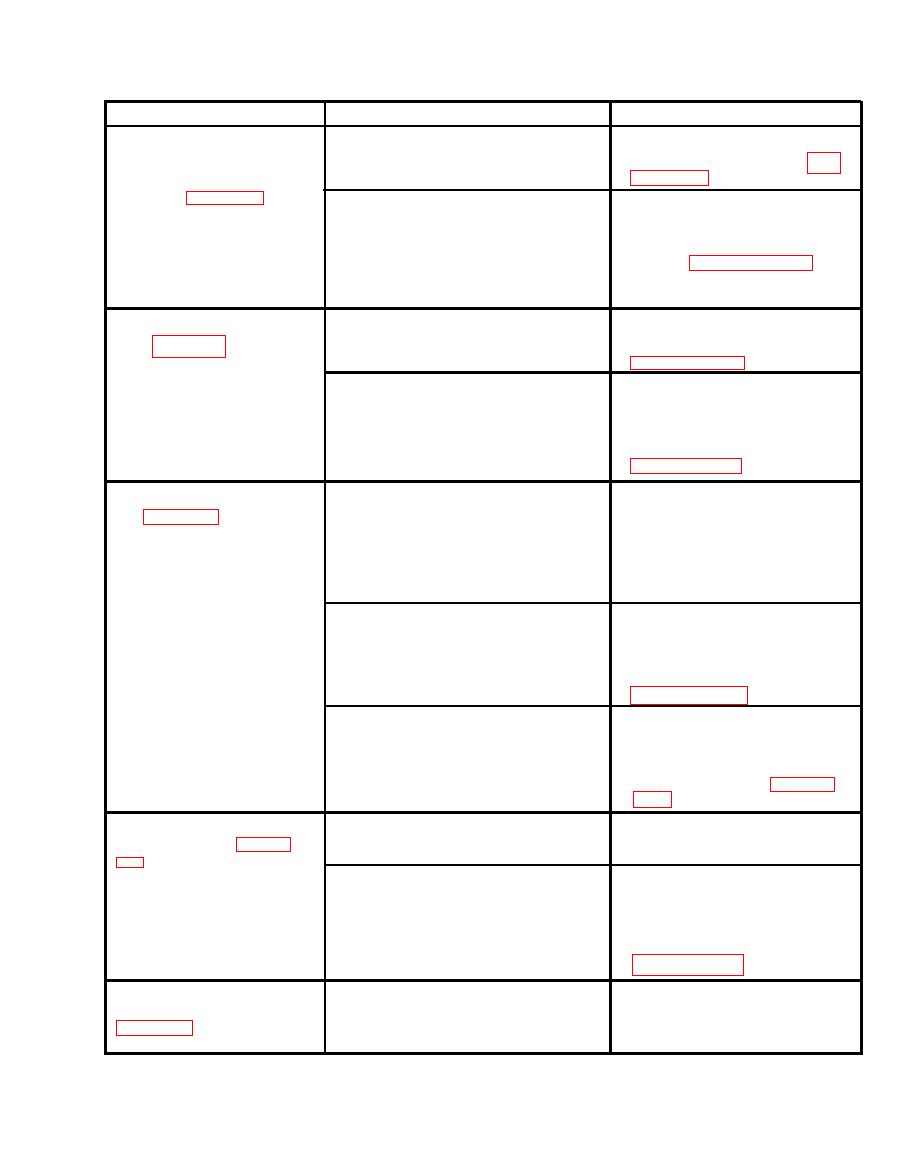

Figure 2-2. Trouble Shooting Chart |

|

||

| ||||||||||

|

|

T.O. 35A2-2-39-11

TM 55-1730-221-12

TROUBLE

PROBABLE CAUSE

REMEDY

Remove screw (22). Adjust

By-pass valve improperly

R a m s (33, 39, 44) fail to

adjusted.

screw (15) as outlined in para-

l i f t when jack is operated,

o r jack fails to lift rated

l o a d . (See figure 3-1.)

Remove screws (15, 22). Re-

Broken by-pass valve spring

(Continued)

(16).

move, inspect, and if necessary

replace spring (16). Install

s c r e w (15) and adjust as out-

lined in paragraphs 3-11a

through 3-11c. Install screw

(22).

R a m s will not fully elevate.

L o w fluid level.

I n s p e c t and fill to correct fluid

( S e e figure 3-1.)

level if necessary (refer to

Leaking discharge valve.

Remove valve assembly (14).

I n s p e c t ball (20) and ball seat-

i n g surfaces of valve body (21).

R e p l a c e ball (20) if defective;

reseat if necessary (refer to

Remove rams (33, 39, 44).

Rams will not support load.

Oil leaks around rams

(33, 39, 44).

Replace packing retainers (37,

( S e e figure 3-1.)

4 3 , 48), and packings (36, 42,

47). Inspect bearings (35, 41,

4 6 ) and bushing (31) for dam-

a g e d grooving or uneven wear.

Replace defective parts.

Leaking discharge valve.

Remove valve assembly (14).

I n s p e c t ball (20) and ball seat-

i n g surfaces of valve body (21).

R e p l a c e ball (20) if defective.

Reseat if necessary (refer to

Leaking release valve ball

Remove, inspect and if neces-

( 2 7 ) or seat.

sary replace ball (27). Inspect

ball seating surface in base

assembly (56) and reseat if

necessary (refer to paragraph

Incomplete closure of

Tighten release valve (25) se-

Rams rise and fall with

release valve (25).

curely.

each stroke. (See figure

Leaking discharge valve.

Remove valve assembly (14).

I n s p e c t ball (20) and ball seat-

i n g surfaces of valve body (21).

Replace ball if defective. Re-

seat if necessary (refer to

V a c u u m created in res-

Unscrew vent assembly (52)

Pump inoperative or dif-

ficult to operate. (See

e r v o i r due to closed vent

vent screw 2 turns.

assembly (52) vent screw.

2-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |