|

|||

|

|

|||

|

Page Title:

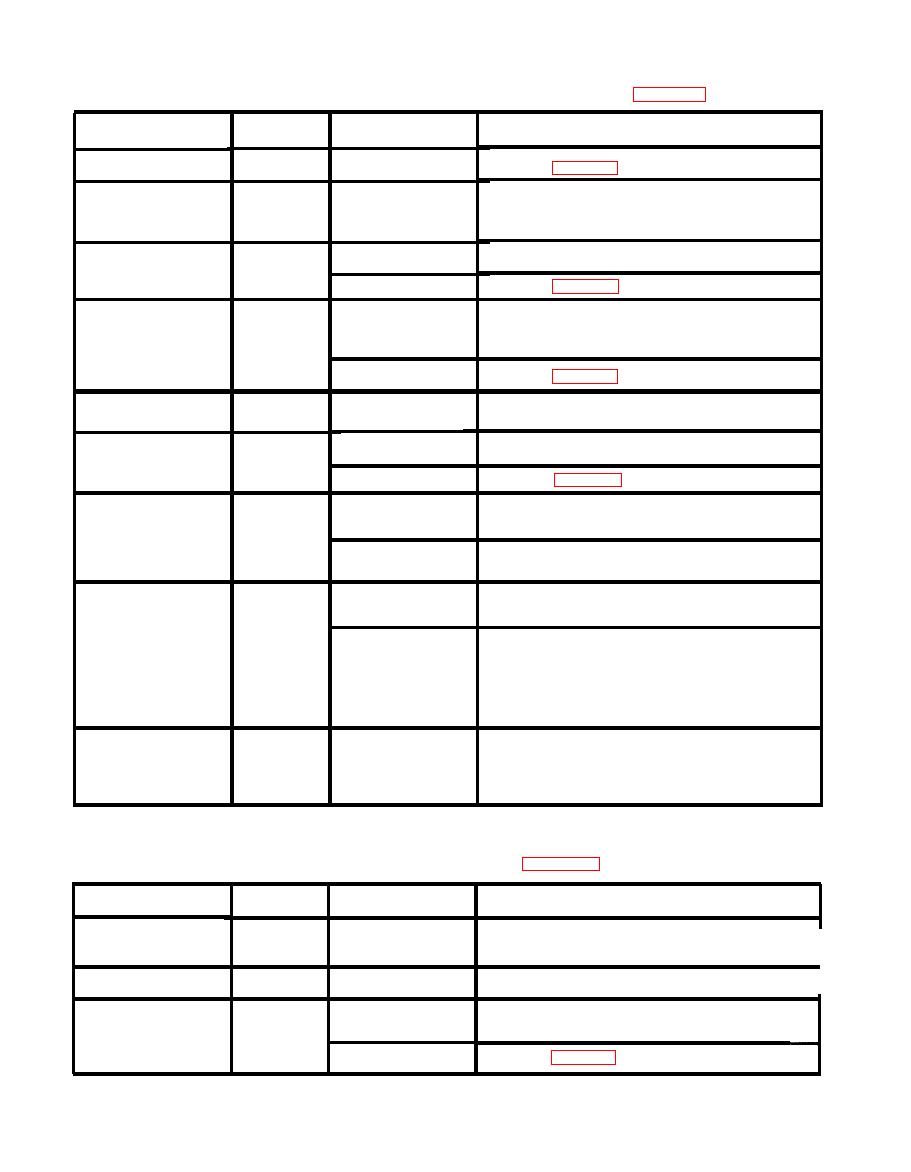

Table 4-4. Jack Component and Hydraulic Lift Detail Inspection |

|

||

| ||||||||||

|

|

T.O. 35A2-2-77-1

TM 55-1730-222-12

Procedure

Test/Check

Part

Index No.

Refer to table 4-5.

2

Detail inspection

Pump assembly

Examine for cracked, gouged, or stripped

Locknuts

Visual

6,7

threads; out-of-round diameters; and for bent

or deformed face flats.

Examine for grooved or scored ID.

8

Visual

Bushing

Refer to table 4-6.

Excessive wear

Examine for grooved or scored shank or

9,15

Visual

Rams

thread crest OD; bending; and for cracked,

gouged, or stripped threads.

Refer to table 4-6.

Excessive wear

Examine for cracks; and for grooved, gouged,

12

Visual

Head

or out-of-round ID.

Examine for grooved or scored ID.

Cylinder

18

Visual

Refer to table 4-6.

Excessive wear

Examine for cracks and deformation; and for

Caster springs

21

Visual

free length of 4.35 inches.

Check for compression to 3.75 inch length at

Compression rate

125 13 pounds load.

Examine for bent stem; and for cracked or

Caster assemblies

22

Visual

gouged tread.

Wheel and swivel

Manually spin caster wheel; rotation of wheel

function

shall be smooth and free; with no evidence of

hesitation, wobble, or oscillation. Swivel

caster horn about stem shaft; there shall be no

evidence of rough spots, binding, or cocked

(non-axial) swivel about caster centerline.

Base and reservoir

23

Examine for cracks; out-of-round or deformed

Visual

holes; and for loose or open base-to-outer

cylinder, leg, footpad, or caster outrigger

weld joints.

r

Part

Test/Check

Index No.

Procedure

Pump link

Visual

Examine for bending and deformation; and

4

for out-of-round holes.

I

Rocker arm

Visual

Examine for out-of-round holes.

6

I

Piston

7

Visual

Examine for grooved or scored minor (wear

surface) OD.

Excessive wear

Refer to table 4-7.

4-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |