|

|||

|

|

|||

|

Page Title:

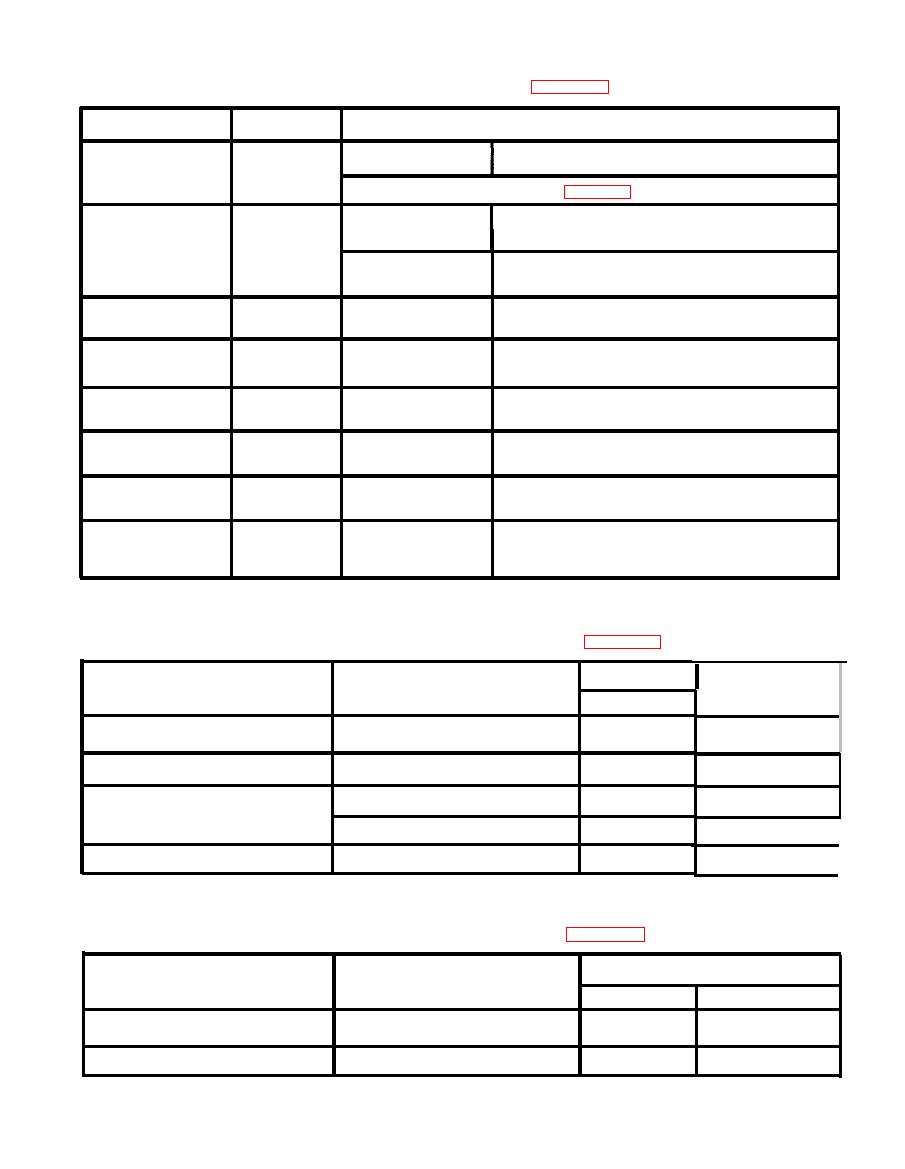

Table 4-5. Pump Assembly Detail Inspection |

|

||

| ||||||||||

|

|

T.O. 35A2-2-77-1

TM 55-1730-222-12

Table 4-5. Pump Assembly Detail Inspection (See figure 5-2.) (Sheet 2 of 2)

Procedure

Test/Check

Part

Index No.

I

Examine for grooved or scored ID.

Pump body

10

Visual

Refer to table 4-7.

Excessive wear

I

Examine for cracks and deformation; and for

14

Visual

Spring

free length of 3/8 inch,

Compression rate

Test for compression to 1/4 inch height under

30-pound load.

Examine for flat spots; and for scratches,

Balls

15,18,25

Visual

nicks, and grooves.

Examine for cracks and deformation; and for

17

Visual

Spring

free length of 1/2 inch.

Examine ball seats for scratches, nicks,

19

Visual

Valve body

grooves, and deformation.

"Examine for cracks and deformation; and for

27

Visual

Spring

free length of 1-1/2 inch.

Examine for raveled, broken wire mesh; and

Oil screen

28

Visual

for deformation, especially at flange end.

Examine for out-of-round holes; and for

Pump block

29

Visual

scratched, nicked, grooved or deformed seat

for release valve ball (25).

Dimension

Limits (in.)

Min

Part Name and Index No.

Dimension Measured

Max

-----

2.248

Bushing (8)

ID

-----

2.233

Major OD

Ram (9)

,

-----

Ram (15)

Major OD

2.988

-----

Wear surface ID

2.398

-----

Cylinder (18)

Wear surface ID

3.148

Dimension Limits (in. )

Max

Min

Dimension Measured

Part Name and Index No.

-----

Piston (7)

Minor OD

0.680

-----

Pump body (10)

Wear surface ID

0.695

4-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |