|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-335-14

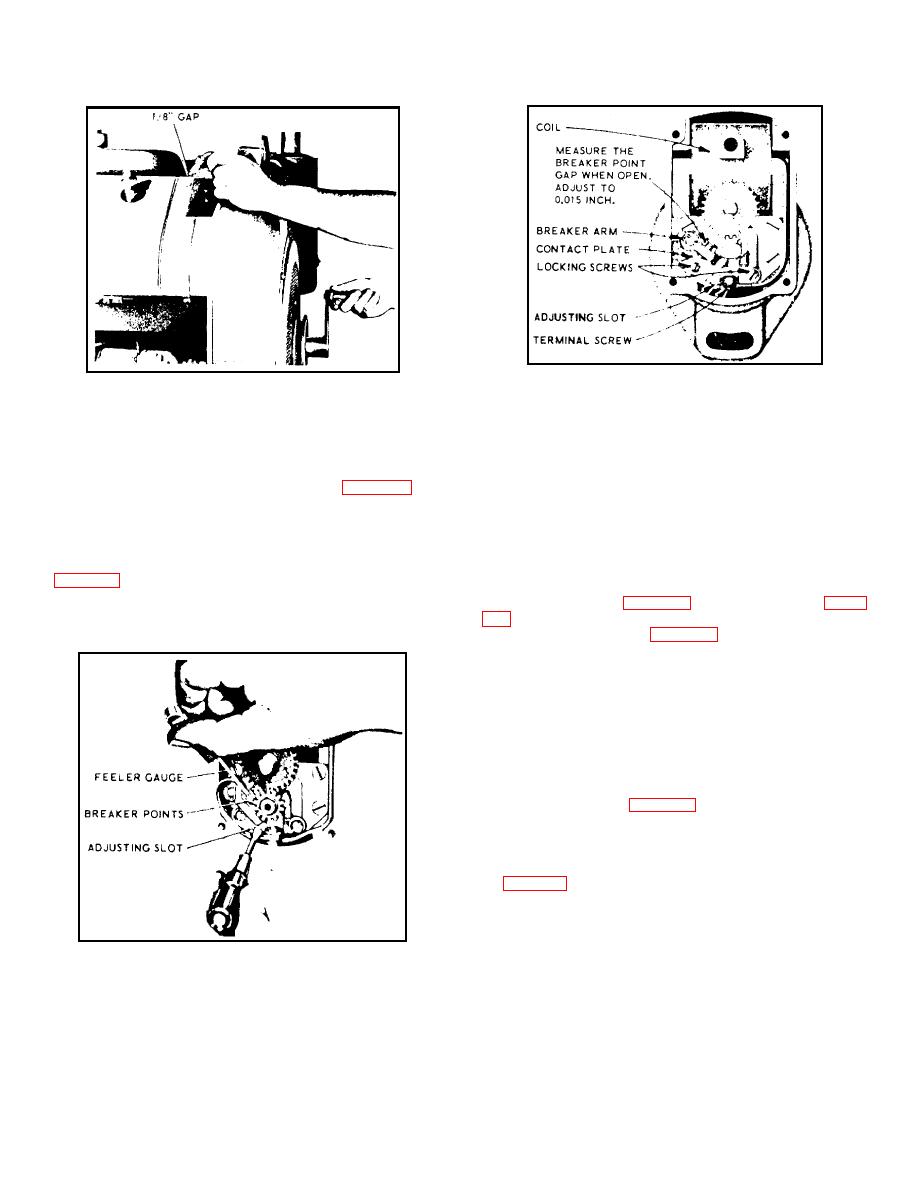

Figure 4-6. Magneto - End View

Figure 4-4. Checking Magneto Ignition Spark

(3) Tighten locking screws and recheck breaker point

b.

Replace points that are badly worn or pitted.

gap to make sure it has not changed.

c. Rotate crankshaft with hand crank (this also rotates

4-14.

ADJUSTING THERMOSWITCH.

An inboard

magneto) until breaker points are wide open. Measure

thermoswitch is installed in the hydraulic manifold and should

opening or gap with a feeler gage as shown in figure 4-5. At

be adjusted so that its contacts open, shutting down the Test

full separation, gap shall be 0.015 inch.

Stand when system hydraulic fluid temperature reaches 71

degrees C (160oF).

Turn adjusting screw in head of

d.

Adjust breaker points as follows:

thermoswitch clockwise to increase temperature setting,

counterclockwise to decrease the temperature setting.

(1) Loosen two locking screws on contact plate

4-15. CLEANING HYDRAULIC RESERVOIR. To clean

(2) Insert end of small screwdriver into adjusting slot

hydraulic reservoir (1, figure 1-4), open access door (2, figure

at bottom of contact plate and open or close contacts by

moving plate until proper gap is obtained.

reservoir shutoff valve (1, figure 3-1) and drain reservoir by

opening drain valve in bottom. Remove top cover plate from

reservoir for access to interior. After cleaning, reassemble and

refill reservoir.

4-16. REPAIR AND REPLACEMENT. Paragraphs 4-17

through 4-19 contain instructions for repair and replacement of

maintenance - significant components for which the

procedures are not obvious.

4-17. GENERATOR REPAIR AND REPLACEMENT. Repair

or replace generator (2, figure 1-4) as follows:

a.

Removal.

(1) Disconnect electrical leads from voltage regulator

(3, figure 1-4).

(2) Remove hardware attaching generator to slotted

bracket and remove fan belt from generator pulley.

(3) Remove mounting hardware securing generator

to rear mounting bracket and remove generator from Test

Stand.

Figure 4-5. Measuring Magneto Point Gap

4-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |