|

|||

|

|

|||

|

Page Title:

GASOLINE ENGINE REPAIR AND REPLACEMENT. |

|

||

| ||||||||||

|

|

TM 55-4920-335-14

(2) Attach starting motor to support bracket with one

(4) Remove four cap screws, lock washers, nuts,

screw and lock washer at rear of motor.

and eight flat washers mounting engine to frame. Use a

(3) Connect electrical lead to motor.

suitable hoist and carefully remove engine from Test Stand.

4-19. GASOLINE ENGINE REPAIR AND REPLACEMENT.

b.

Disassembly.

Remove and repair gasoline engine (1, figure 1-3) as follows:

(1) Remove starting motor and magneto. Remove

a.

Removal.

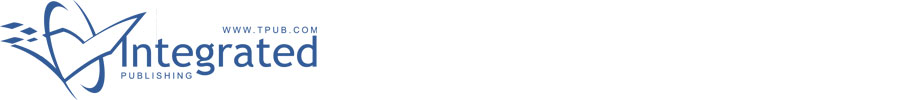

cylinder head covers and screws mounting flywheel shroud to

lower cylinder shrouds and heat deflectors. Remove front end

(1) Remove Test Stand housing. Remove muffler (2,

panel as shown in figure 4-7. Remove balance of shrouding.

Drain crankcase oil.

(2) Disconnect oil lines from oil filter (9, figure 1-3).

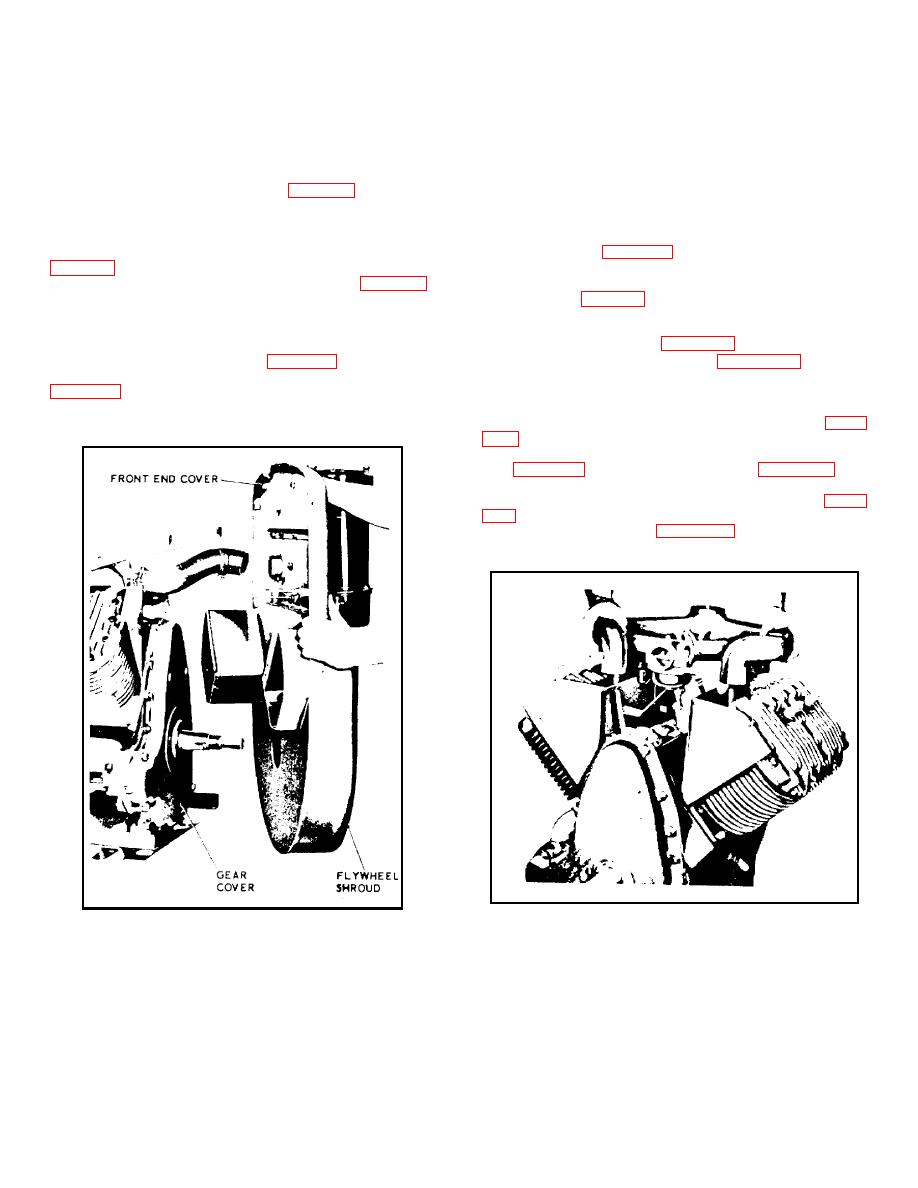

(2) Remove carburetor and manifold as an

Disconnect fuel line from fuel pump. Disconnect choke and

assembly. See figure 4-8. Remove cylinder heads.

throttle cables from engine. Disconnect electrical lead to

(3) Disconnect governor linkage and remove

starting motor. Disconnect electrical leads from control panel

governor assembly. Remove gear cover screws and drive out

indicators and switches at engine.

two dowel pins as shown in figure 4-9. Remove gear cover

(3) Loosen generator (2, figure 1-4) in slot of front

exposing timing gears as shown in figure 4-10. Remove

bracket and remove fan belt. Support high pressure pump (8,

camshaft thrust plunger and spring to prevent loss.

(4) Remove setscrew on magneto side of crankcase

pump mount to rear of engine. Disconnect flexible coupling

which locks idler shaft in position. Remove idler gear

between pump shaft and engine crankshaft.

assembly and idler shaft using a gear puller as shown in figure

(5) Invert engine and remove oil pan and supports.

See figure 4-12. Take out slotted pipe plug (figure 4-13) and

then, use a 5/32 inch allen wrench to remove oil pump lock

screw. Remove lock nut holding oil pump driving gear (figure

through gear as shown in figure 4-14. Withdraw oil pump

toward center of crankcase.

Figure 4-8. Removing Carburetor and Manifold

Figure 4-7. Removing Flywheel Shroud

4-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |