|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-335-14

(8) Install gear cover (figure 4-9) and tighten gear

cover cap screws 14 to 18 foot pounds torque. Install governor

FULL

NO

HOLE

and governor housing.

LOAD

LOAD

No

(9) Remove all carbon and lead deposits from

R.P.

R.P.1.

cylinder heads. Use a new cylinder head gasket at assembly.

1400

1550

4

Apply a mixture of graphite and oil to cylinder head screws to

1500

1650

5

prevent them from rusting tight against cylinder block. Tighten

cylinder head screws 25 to 32 foot pounds torque and, after

1600

1725

5

complete assembly and engine is run-in, retorque head

1700

1850

6

screws.

(10) Install carburetor and manifold assembly figure

1800

1950

7

1900

2050

8

torque. Overtightening may cause flanges to break.

(11) Install magneto and starting motor.

Install

2000

2125

8

shrouding (figure 4-7).

2100

2250

9

2200

2350

10

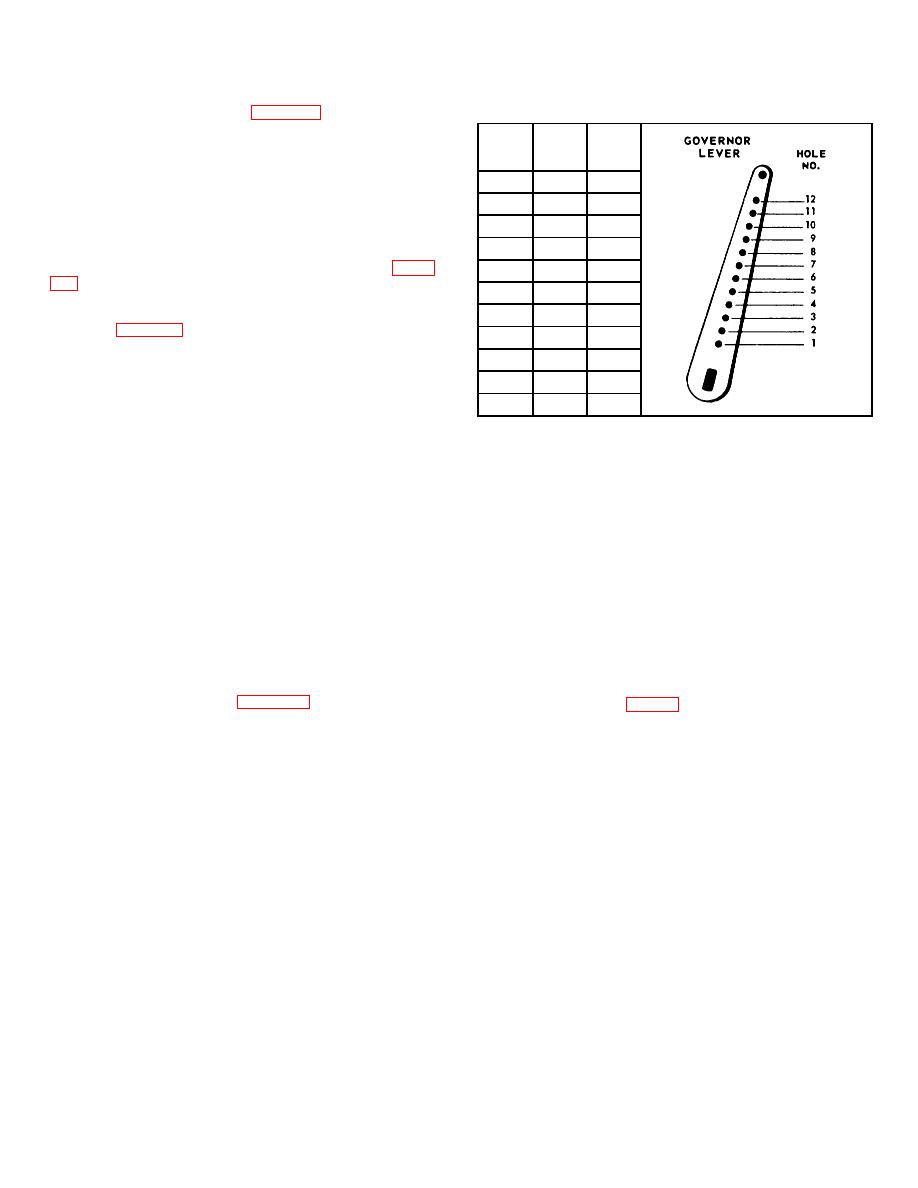

e. Governor Adjustment.

The control rod between

governor and carburetor must be adjusted to proper length.

2300

2425

10

With engine at rest, the governor spring will hold flyweights in,

2400

2550

11

and control rod must be of such length as to hold carburetor

throttle wide open at that point.

The accuracy of this

Figure 4-23. Governor Lever Chart

adjustment can be tested as follows:

f. Installation.

(1) Disconnect control rod ball joint from governor

lever and push rod assembly toward carburetor as far as it will

(1) Use a suitable hoist and carefully position engine

go. This will open throttle wide.

onto frame of Test Stand. Secure engine to frame with four

(2) Move governor lever as far as possible in same

cap screws, lock washers, nuts, and eight flat washers.

direction as control rod. Holding both parts in this position,

(2) Connect flexible coupling between high pressure

screw ball joint onto control rod until right angle stud on ball

pump shaft and engine crankshaft. Attach pump mount to rear

joint fitting will register with hole in lever then, screw fitting in

of engine using four screws and lock washers. Position fan

two more turns.

belt over engine pulley and generator pulley and tighten

(3) Insert ball joint stud into hole in governor lever,

generator in slotted bracket while putting tension on belt.

assemble and tighten lock nuts. With governor lever pushed

(3) Connect electrical leads to engine and starting

toward carburetor as far as it will go, there should be 1/16 inch

motor. Connect throttle and choke cables. Connect fuel line to

clearance between throttle lever and stop pin on carburetor.

fuel pump. Connect oil lines to oil filter. Install muffler. Refill

(4) The governor lever is furnished with 12 holes for

crankcase with oil.

attaching governor spring. It is important that spring is hooked

into proper hole to suit speed at which engine is operated.

4-20. LUBRICATION. Table V is a lubrication chart indicating

Insert spring in hole number 7, figure 4-23.

lubricant specification, time of application, quantity and point of

lubrication.

4-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |