|

|||

|

|

|||

|

Page Title:

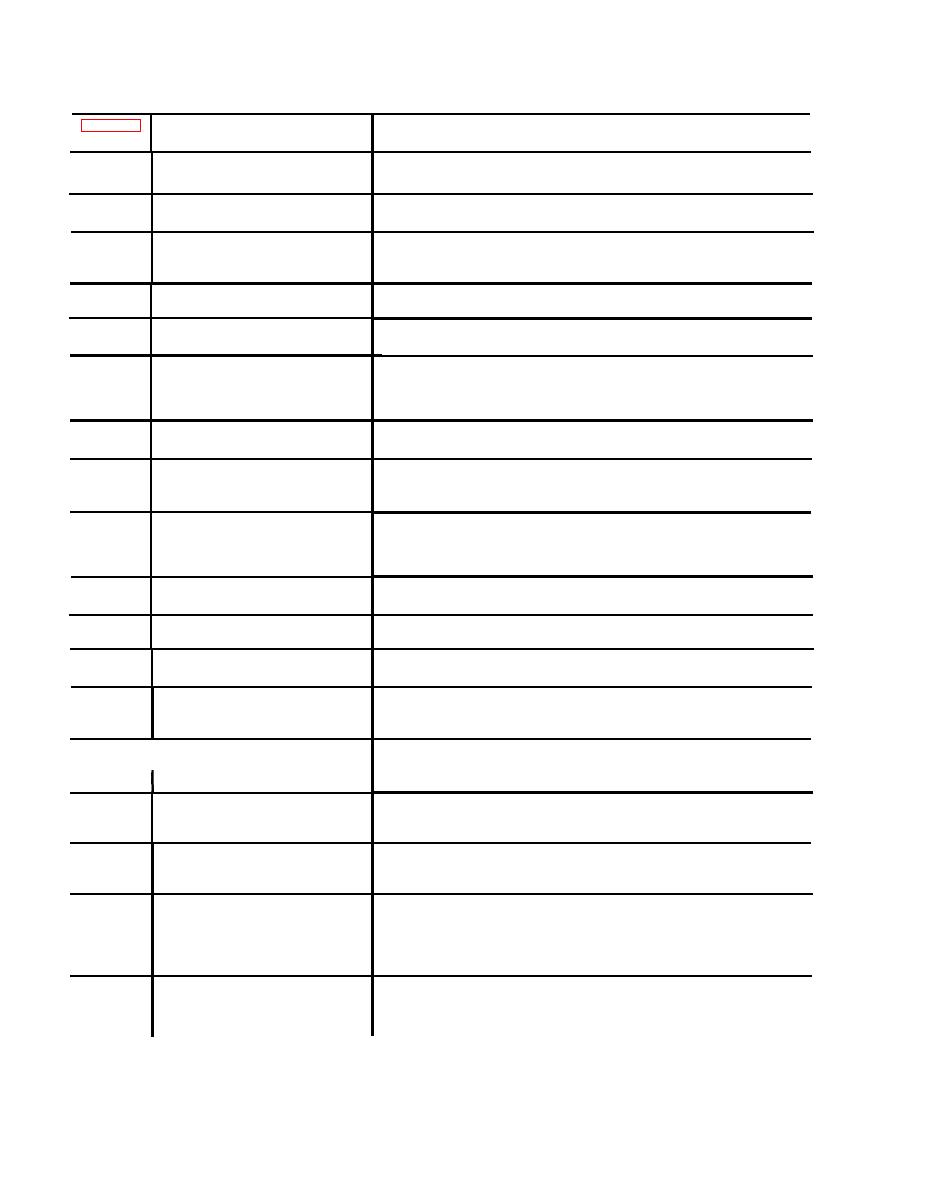

Table 2-1. Function of Main Panel Controls and Instrumentation |

|

||

| ||||||||||

|

|

TM 55-4920-405-13&P

Function of Main Panel Controls and Instrumentation

Table 2-1.

Description

Index No.

Function

1

TACHOMETER/HOUR

Dual purpose instrument; indicates engine speed (0-2500

METER

RPM) and elapsed operating time of test stand

2

ENGINE OIL PRESSURE

Direct reading gage indicates engine oil pressure; normal

pressure is shown by green region on gage

gage

3

Direct reading, 30-0-30 ampere meter, located in battery

charging circuit; normal reading during operation is at

some point to right of zero

4

FUEL LEVEL gage

Indicates amount of gasoline in gas tank of test stand; full

tank provides at least four hours of operation

5

FLUID PRESSURE GAGE

High pressure (0-6000 PSI) fluid gage; measures output

pressure of test stand

Provides means for connecting external gage for calibra-

6

HP GAGE CAL PORT

tion of FLUID PRESSURE GAGE; make sure cap on this

port is securely fastened during normal operation of test

stand

SUCTION PRESSURE GAGE

7

Direct reading gage (0-30 inches of vacuum, 0-150 PSI

p r e s s u r e ) ; measures suction pressure of test stand

8

SUCT PRESS CAL PORT

Permits connection of external gage for calibration of

SUCTION PRESSURE GAGE; make sure cap on this port

is securely fastened for normal operation of test stand

9

FLUID TEMP GAGE

Measures temperature of hydraulic fluid over range of

-20 to +250F, with red warning zone beginning at

+160F; never allow fluid temperature to rise above

+160 F

Indicates level of hydraulic fluid in reservoir of test stand

RESERVOIR FLUID LEVEL

10

INDICATOR gage

Indicates rate of flow of hydraulic fluid in GPM at 1800

11

FLOW INDICATOR GPM

RPM

Controls flow of hydraulic fluid from test stand; locking

12

FLOW CONTROL VALVE

device is provided to lock control knob at selected setting

Lights when high pressure filter differential fluid pressure

13

HP P indicator

reaches 40 PSI, indicating need to replace high pressure

filter element

I

14

Positions cam plate of hydraulic pump to provide desired

VOLUME control

output volume; locking device is provided for locking

control at selected setting

15

RESERVOIR valve

When set to OUT, shuts off test stand reservoir to per-

mit use of external reservoir; when set to IN, turns on

test stand reservoir

16

PRESSURE COMPENSATOR

Provides means of adjustment to obtain desired discharge

pressure; locking device is provided for locking control

at selected setting

Used to isolate pressure compensator from hydraulic

17

COMPENSATOR SHUTOFF

system and establish setting of HIGH PRESS RELIEF

VALVE

VALVE; when closed, prevents hydraulic pump from

compensating, thereby allowing pump to go to maxi-

mum pressure

18

Adjustable, bypass type relief valve that serves as

HIGH PRESS RELIEF VALVE

safety device, protecting hydraulic system under test

from excessive pressure; knurled locknut is provided

to lock valve at selected setting

2-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |