|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-405-13&P

4-3. TROUBLE ANALYSIS.

Red leadwire to black leadwire -

no

continuity

a . Electrical System. Locate defective parts

Black leadwire to red leadwire -

no

of the electrical system as follows:

continuity

Black leadwire to engine ground

- no

(1)

Battery. Check the specific gravity of the

continuity

battery with a hydrometer. The specific

Engine ground to black leadwire

-

gravity of each cell should be between

continuity

1.285 and 1.300. If it is below 1.285,

charge the battery. If the battery fails to

If any of these readings is not obtained,

take a charge, replace the battery.

the voltage regulator is bad.

(2)

(5)

Ignition Wire Assembly. Check for con-

R e c t i f i e r . With the rectifier plug discon-

tinuity from end to end of each ignition

nected from the rest of the electrical sys-

tem, check ohmmeter readings between

wire with an ohmmeter. You should get a

continuity (less than 1 ohm) indication for

the following points:

each wire. If you do not, the ignition wire

is defective.

White leadwire to black 1

leadwire - no

(3)

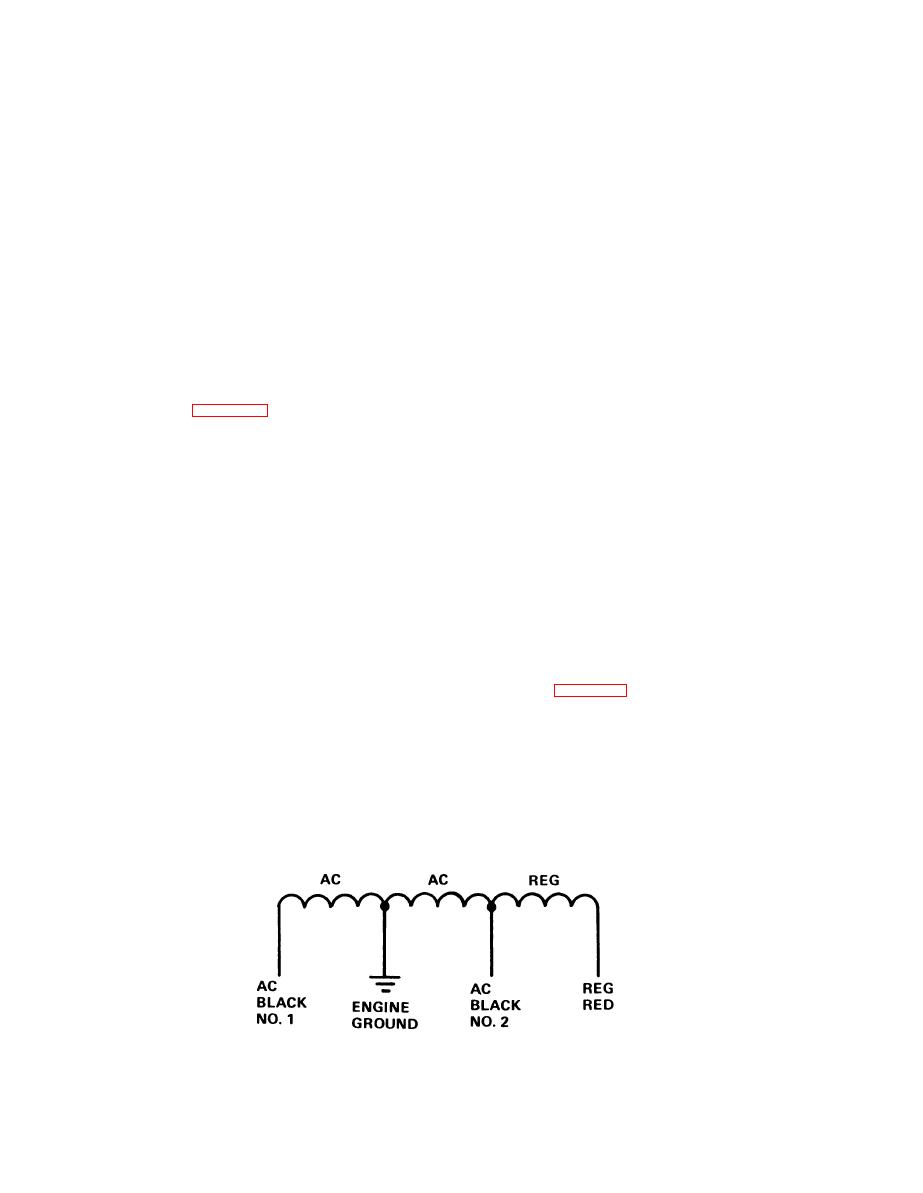

Alternator. The alternator is made up of

continuity

two major parts: a rotor and a stator.

Black 1 leadwire to white

leadwire -

Check to see that each separate cut be-

continuity

tween the rotor electromagnets is free of

White leadwire to black 2

leadwire - no

dirt. See figure 4-2 for the schematic

continuity

diagram of the stator. Wire numbers

Black 2 leadwire to white

leadwire -

shown on the schematic diagram are for

continuity

convenience in referencing only. These

numbers do not appear on the wires.

NOTE

Squeeze the outer ends of the plug recept-

Continuity should be in one direction only.

acles on the alternator leadwires, and

pull the plugs apart. Then, check the

If you do not get these readings, the recti-

resistance of the stator windings with an

fier is bad.

ohmmeter. The approximate resistance

(6)

readings are:

Starter Switch, Solenoid, and Motor. If

you think that the starter circuits may be

Black

1

to

black 2 - 0.40 ohm

bad, use a DC voltmeter to trace voltage

Black

1

to

engine ground - 0.20 ohm

in these circuits. Set the IGNITION

Black

2

to

engine ground - 0.20 ohm

SWITCH to ON. Hold in the STARTER

switch, and check for 12 volts DC (mea-

Black

1

to

red - 3.20 ohms

sured to ground) at the input and output

Black

2

to

red - 2.80 ohms.

terminals of the STARTER solenoid, and

If you get an open indication between any

at the input terminal of the starter motor.

of these measurement points, the alter-

(See figure 4-3.) You should get a 12 volt

reading at each of these points. If you do

nator is bad.

(4)

Voltage Regulator. To test the voltage

and the starter motor does not turn over,

regulator, use an ohmmeter and check to

the starter motor is bad. If you get a 12

see that you get the following ohmmeter

volt reading at the input of the STARTER

solenoid, but not at the output terminal of

readings between the listed points:

the same part, that part is bad.

Electrical Wiring and Cables. To check

Red leadwire to engine ground - no

(7)

the electrical wiring and cables, discon-

continuity

Engine ground to red leadwire - no

nect the battery cables from the battery

terminals. Then, check each wire and

continuity.

Figure 4-2. Alternator Stator, Schematic Diagram

4-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |