|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-405-13&P

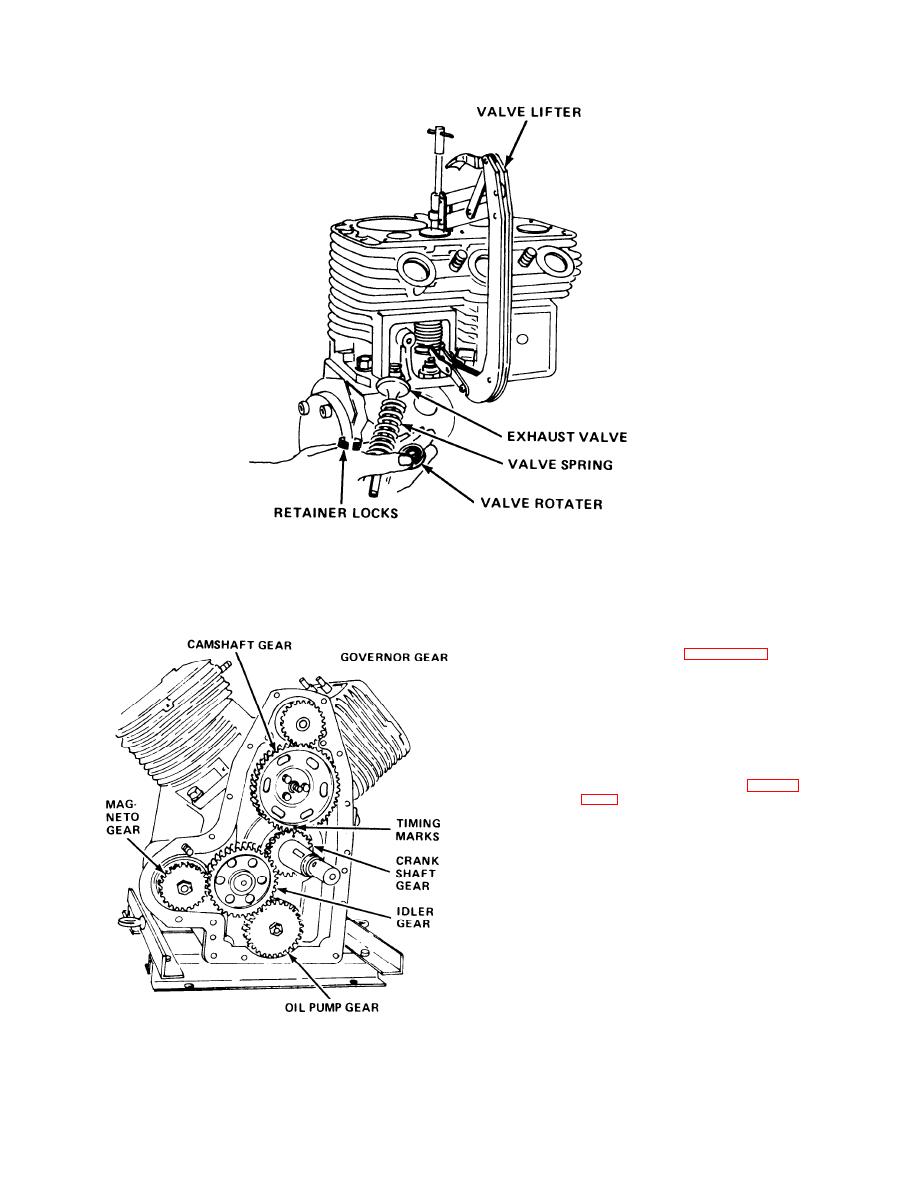

Figure 4-15.

Removal of Valves

(h)

Lift the camshaft out from the fly-

wheel end of the crankcase.

(i)

Examine all parts for damage or ex-

cessive wear. Replace all damaged

or worm parts. See figure 4-24 for

correct piston, ring, and rod

clearances.

Reassemble the crankcase assembly,

(j)

noting the following:

1.

When you are installing the cam-

shaft, make sure that the spring

and plunger are in place in the

end of the camshaft. (See figure

shaft in position endwise.

2.

Install the valve tappets after the

camshaft is installed.

3.

When you are installing the crank-

shaft, use gaskets and-shims of

the thickness needed to set the

end plate of the tapered roller

bearings at 0.002 to 0.004 inch.

4.

Make sure that you install the

main bearing plate with the word

"TOP" which is cast on the out-

side of the plate, in the up posi-

tion. If you install this plate up-

side down, the main bearing will

not be properly lubricated.

Tighten the main bearing plate

screws to a torque of 25 to 30

Figure 4-16.

Crankcase Assembly Gears

foot-pounds.

4-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |