|

| |

TM9-6115-667-13&P

REPLACEMENT

Note: Be sure all machined surfaces are clean, free of

burrs and damage.

1.

Turn the capscrew (22) about halfway into the

Hyrevz motor (31) drive shaft; then slip the rotor

assembly (24) onto the Hyrevz motor drive shaft.

2.

Install the "C" washer (23) onto the capscrew

(22) between the bolt head and the hydraulic motor drive

shaft. Tighten the capscrew with a thinwall 1/ 2-inch end

wrench.

3.

Position the stator (13) so that stickers (11 & 12)

are positioned as shown on page 3 of this manual. Slip

the stator (13) over the rotor assembly (24) and onto the

inboard motor end adapter (26) pilot. Seat into place by

lightly tapping with a soft-faced mallet.

4.

The webs of the outboard bearing bracket

assembly (7) resemble the letter ’Y". Position the

outboard bearing bracket assembly (7) so the vertical

portion of the ’Y’ is at the bottom of the bracket.

5.

Align the outboard bearing bracket assembly (7)

stub shaft with the rotor assembly (24) bearing inner race

bore and the bearing bracket pilot with the stator (13).

6.

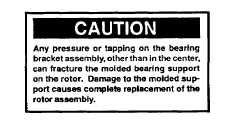

Carefully and lightly tap on the outboard bearing

bracket assembly (7), center only, until the bracket seats

on the stator (13).

7.

Secure the stator between the outboard bearing

bracket assembly (7) and receptacle box (5) and the

inboard engine end adapter (26) using the four 1/4-20 x

9-1/2 inch/32 cm long stator bolts (4) and nuts (29).

Note: The stator bolt holes must line up on both

surfaces.

8. Perform steps 1 and 2 of the RECEPTACLE PANEL

REPLACEMENT procedure to complete the reassembly.

HYREVZ™ MOTOR

REMOVAL, DISASSEMBLY,

INSPECTION, CLEANING,

Obtain Seal Kit, part number 07388, to replace all seals

exposed during disassembly. Note orientation of seals

before removing them. Install new seals in the same

way.

REMOVAL

1.

Perform steps 1 through 7 of the ROTOR

REMOVAL procedures and lay the removed assemblies

aside.

2.

Remove the four 3/8-16 x 2 inch/51 mm long

capscrews (25) securing the inboard engine end adapter

(26) to the motor adapter plate (30).

3.

Lift the Hyrevz motor (31) and attached motor

adapter plate (30) up and away from the inboard engine

end adapter (26).

4.

Place the Hyrevz motor (31) in a vise (with soft

jaws or V-blocks) with the motor adapter (30) up.

5.

Remove the two 5/16-18 x 3/4 inch/19 mm long

capscrews (28) securing the motor adapter plate (30) to

the Hyrevz motor (31).

DISASSEMBLY

1.

Place the Hyrevz motor (31) in the vise so the

soft jaws or V-blocks are around the bearing housing (9)

end with the drive shaft down.

2.

Remove the eight 1/4-20 x 2-1/4 inch/57 mm

long capscrews (5, figure 3) securing the gear housing

assembly (1) and bearing housing (9).

3.

Using a flat-blade screwdriver or similar tool,

gently pry the gear housing assembly (1) away from the

bearing housing (9). Lift the gear housing assembly (1)

straight up.

Do Not tilt the housing or pry on the flat surface inside of

the surrounding groove. For prying, only use the groove

provided at the split between the parts to prevent

scratches on the inner mating’ surfaces.

9

|