|

| |

TM9-6115-667-13&P

4.

Remove the idler gear (7), drive gear (8), needle

roller key (12), and the idler shaft (6).

5.

Remove the large o-ring (4) while being careful

not to damage the o-ring groove or surrounding surface.

6.

Remove the bearing housing (9) from the vise.

While protecting the mating surface from damage,

remove the retaining ring (10) from around the bearing.

Hold the bearing housing and tap lightly on the small

diameter end of the drive shaft (11) to remove it and the

bearing (13) from the front of the bearing housing.

7.

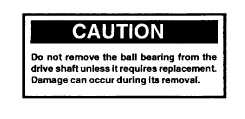

To remove the bearing (13) from the drive shaft

(11), remove the retaining ring (14) on the drive shaft

next to the bearing. Press on the gear end of the drive

shaft while supporting the outer race of the bearing.

Discard the old bearing.

8.

Remove the retaining ring (15) at the bottom of

the bearing bore to service the seal gland (16), o-ring

(17) and quad ring (18). Remove the seal gland (16)

using typical o-ring service tools to pry it out of its bore.

Take care to avoid damaging the seal surfaces. Note

seal orientation. Remove the o-ring (17) from the

outside of the seal gland. Remove the quad ring (18)

from the inside of the seal gland.

9.

If the bushings (3) are to be replaced, remove

the four bushings (3) from the bearing housing (9) and

gear housing assembly (1) using a typical bushing

removal tool with a 7/16 inch collet.

INSPECTION AND CLEANING

Inspect and clean all parts as follows:

Cleaning

Clean all parts with a degreasing solvent. Blow dry with

compressed air and wipe clean. Use only lintfree cloths.

Gear Housing Assembly (1, figure 3)

The chamber bores and bottoms around the shaft

bushings (3) should be polished and not rough or

grooved. If the bushing bores are yellow-bronze, replace

them and investigate the cause of wear.

The flat surfaces at each end of the gear housing

assembly (1) should be flat and free of nicks or burrs that

could cause misalignment or leaks.

Bushings (3, figure 3)

The inside of the bushings should be gray with some

bronze showing through. If significant yellow-bronze

shows, replace the bushings.

Inspect drive shaft (11) for corresponding wear and

replace as required.

Gears (7 & 8, figure 3)

The drive gear (8) and idler gear (7) should have straight

tips without nicks; square tooth ends and a smooth even

polish on the teeth and end faces. Check for cracks

between the drive gear keyway and gear tooth root.

Replace the gear if cracks are present.

Bearing Housing (9, figure 3)

The

surface

near

the

gears

should

show

two

interconnecting polished circles without a step.

The bottom of the o-ring groove should be smooth as

should the rest of the flat surface.

The bore for the drive shaft seal (inside of the seal gland

[16] ) should be smooth or oil leakage may occur. The

bore in which the seal gland fits should also be smooth.

Shake the bearing housing and a rattle should be

10

|