TM 3-5180-210-15

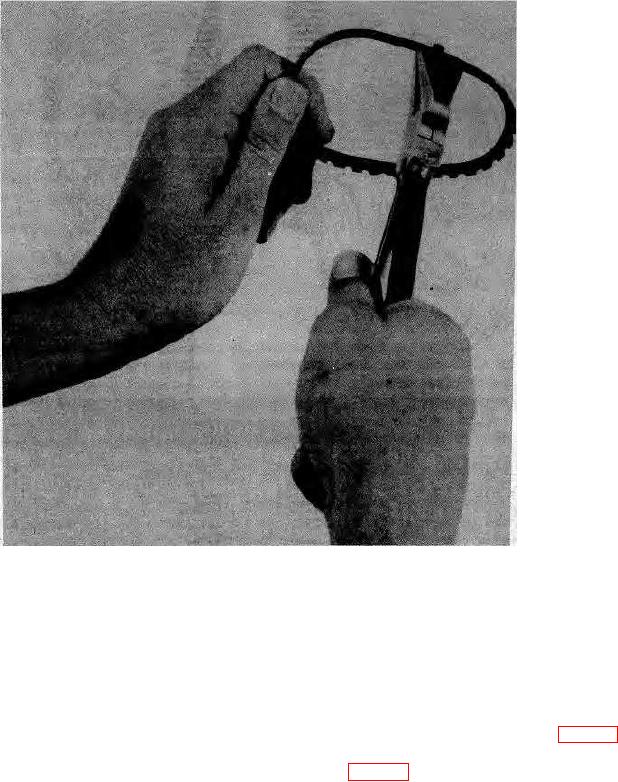

Figure 6. Bending large tabs with glass pliers.

this elongated position for approximately 5 seconds. If

Note. When the press reaches the preset

the nosecup does not separate from the facepiece (a

pressure, it will automatically release. This adjustment

popping sound is usually heard if the nosecup does

prevents applying too much pressure for the crimp.

separate from the facepiece), the crimp is satisfactory.

Visual check of the gage provides assurance that the

If the crimp is not satisfactory, rework the mask.

correct amount of pressure is being applied.

(2) Install mask components necessary for

(6) Release and raise the upper die. Unlock

testing.

the lower die, and remove the mask from the crimping

(3) Test the mask for leakage (para 18).

outfit.

(4) Install mask components that were

d. Checking.

removed (para 16) as applicable.

(1) Check to make sure that the nosecup

(5) Install the head harness.

assembly and the voicemitter-outlet valve assembly

have been crimped to the facepiece satisfactorily.

Reach into the cavity of the mask between the

18. Testing Masks for Leakage

facepiece and the top of the nosecup. Elongate the

Test the mask for leakage using the M14 protective

nosecup (approximately 1/4 inch) -with the middle finger

mask leakage tester.

by pressing the nosecup as close as possible to the

voicemitter-Outlet valve frame. Hold the nosecup in

10