|

|||

|

|

|||

|

Page Title:

Chapter 3. OPERATOR AND ORGANIZATIONAL MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

OPERATOR AND ORGANIZATIONAL

MAINTENANCE INSTRUCTIONS

Section I. SPECIAL O R G A N I Z A T I O N A L T O O L S A N D E Q U I P M E N T

No special tools or equipment are required to perform organizational maintenance of this

aircraft hydraulic test stand.

Section Il.

LUBRICATION

c. Points of Application. Follow the detailed

51. General

lubrication instructions given in the applicable

This section contains lubrication instructions

maintenance paragraphs and refer to the lubri-

which are supplemental to and are not specifi-

cation chart for type of lubricant and interval

cally covered in the lubrication chart.

of application.

d. Operation After Lubrication. Operate the

52. Detailed Lubrication Information

test stand for 5 minutes immediately after

lubrication. Inspect the oil filter for leaks and

lubricant containers after use and store in a

correct as necessary. Stop the unit, wait 5

clean, dry place. Keep all containers, used in

minutes, and check the oil level. Add oil to

handling lubricating oil or gasoline, clean and

bring the oil level up to the FULL mark if nec-

ready for use.

essary.

e. Oil Filter.

b. Cleaning. Use an approved cleaning sol-

(1) Loosen the bolt (27, fig. 11) and re-

vent to wipe all surfaces clean surrounding the

move the cover (26) from oil filter

point of application before applying the lubri-

(24).

cant.

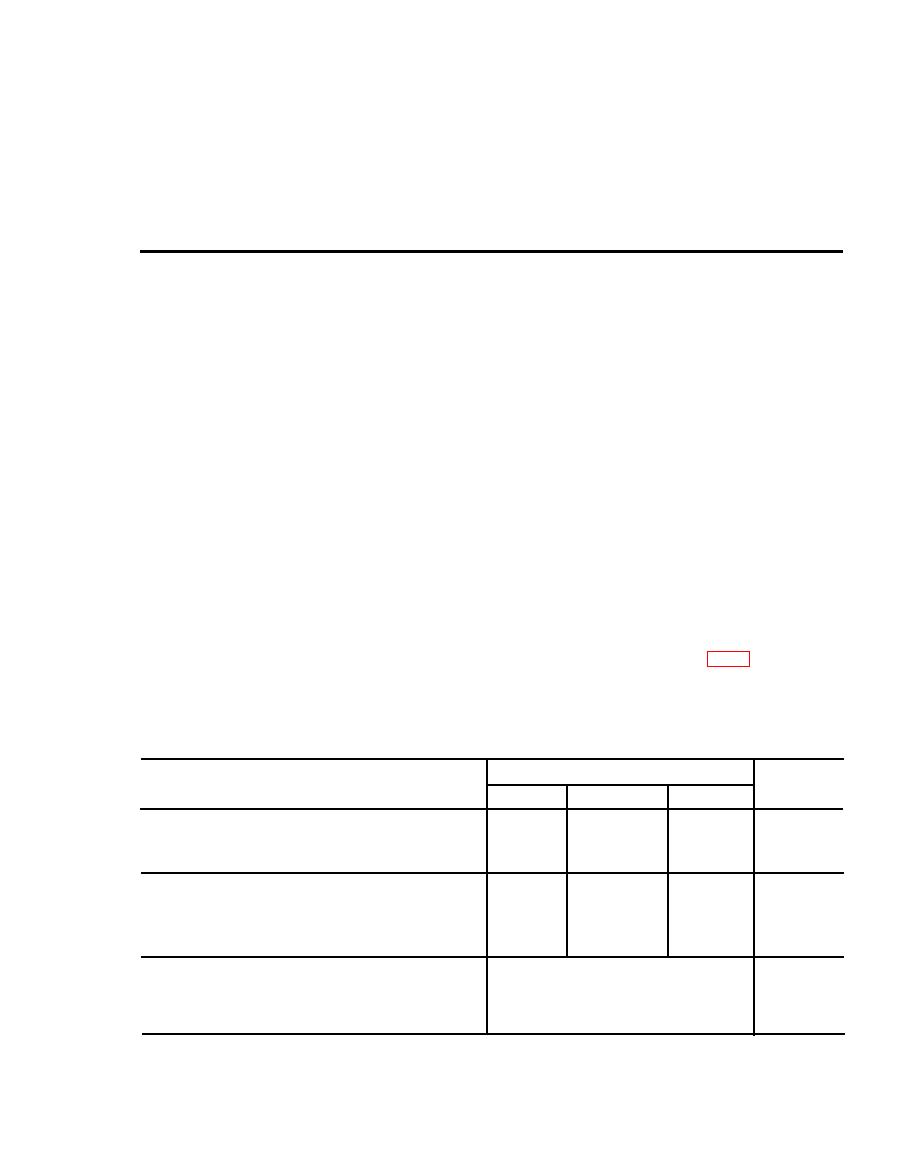

Table 1. Lubrication Chart

Expected

Temperatures

Intervals

A b o v e + 3 2 F . + 4 0 F t o -- 1 0 F . 0 F. to --65 F.

OE--OIL, Engine, Heavy Duty Engine Crankcase

50 hours

OE30

OE10

OES

Air Cleaner

50 hours

OES--OIL, Engine, Subzero

2190--LUBRICATING OIL, General Purpose

Flow Indicator

50

hours

Drawbar Assembly

100

hours

Door Hinges and Latches

2110

2190

2075

100

hours

Engine Generator

100

hours

GAA--GREASE, Automotive and Artillery

Wheel Bearings

100 hours

Tie Rod Ends

All Temperatures

100 hours

Spindles

100 hours

AGO 5742A

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |