|

|||

|

|

|||

|

Page Title:

Chapter 4. DIRECT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

DIRECT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTIONS

Section I. SPECIAL DIRECT AND GENERAL SUPPORT

MAINTENANCE TOOLS AND EQUIPMENT

No special tools are required to perform direct and general support maintenance of this hy-

draulic test stand.

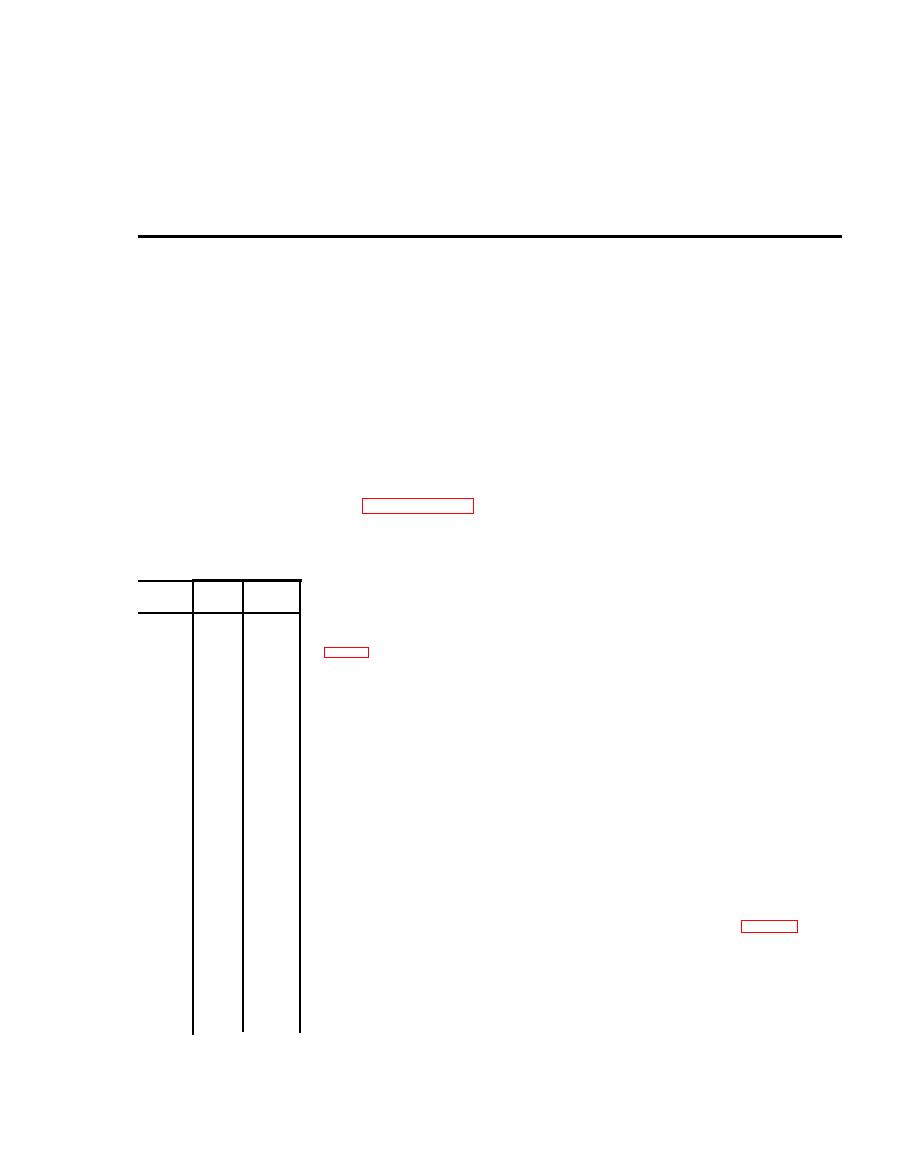

Section Il. PREVENTIVE MAINTENANCE SERVICES

vialed for the information of the person per-

77. General

forming the inspection. An X in this column

P r e v e n t i v e maintenance is performed by

indicates that an inspection should be made of

direct and general support maintenance person-

the listed items in accordance with instructions

nel at 50 and 100 hour intervals. The preventive

given in the text opposite. The indicated items

maintenance services to be performed at these

and instructions constitute minimum inspection

requirements for the equipment.

The first column headed "inspection", is pro-

GENERAL

50 hour

Inspection

100 hour

x

x

x

Before-operation services. Perform the services listed in daily before-operation services

(par. 54).

x

x

x

Lubrication. Inspect for missing or damaged lubrication fittings and inspect for indi-

cations of improper lubrication. Inspect lubricant level in engine crankcase. Inspect

for oil and grease leaks; also inspect for defective or damaged oil seals.

x

x

Lubricate as necessary in accordance with the lubrication chart. Replace missing or

damaged fittings. Correct all oil or grease leaks.

x

x

x

Appearance. Inspect the general appearance of the equipment, paying particular

attention to cleanness, legibility of identification markings, and conditions of the

paint. Correct all deficiencies noticed.

x

x

x

muffler mounting bolts and nuts. During the first weekly servicing of a new or

reconditioned engine, inspect all the cylinder head bolts for tightness . After warming

up the engine to operating temperature, tighten any loose bolts to 25 to 32 ft-lb

torque. Replace defective cylinder head and manifold gaskets.

x

x

x

Valve mechanism. If the valves are noisy or loss of power is noticed, inspect the

condition of the valve mechanism.

x

x

Remove valves covers and adjust valve lifter clearance if necessary (par. 125). The

correct clearance for the valve lifters is 0.0080 inch for the intake valves and 0.0160

inch for the exhaust valves. Replace cover gaskets if defective.

x

x

Compression test. Remove the spark plugs and test the cylinder compression by turning

the engine over several times to stabilize gage reading. If the gage reading varies

more than 10 pounds between the four cylinders, inspect the cylinder head bolts for

tightness.

AGO 5742

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |