|

|||

|

|

|||

|

Page Title:

Section IV: PERIODIC INSPECTION, MAINTENANCE, AND LUBRICATION |

|

||

| ||||||||||

|

|

TM 55-4920-335-14

SECTION IV

PERIODIC INSPECTION, MAINTENANCE, AND LUBRICATION

4-1. PERIODIC INSPECTION. Periodic inspection consists of

4-3. SERVICING FUEL FILTER. The engine fuel filter bowl

inspection and services to be performed daily, every 50 hours,

should be inspected frequently and cleaned if dirt or water are

and every 100 hours of Test Stand operation as outlined

present.

in Table IV. The hourly time is obtained by noting the tach-

hourmeter (21, figure 3-1) located on the control panel.

a.

Shutoff fuel valve at top side of filter.

4-2. MAINTENANCE. Maintenance procedures outlined in

b. Loosen knurled nut below bowl and swing wire bail to

one side.

c. Remove bowl and screen. Empty bowl and clean

screen and bowl thoroughly.

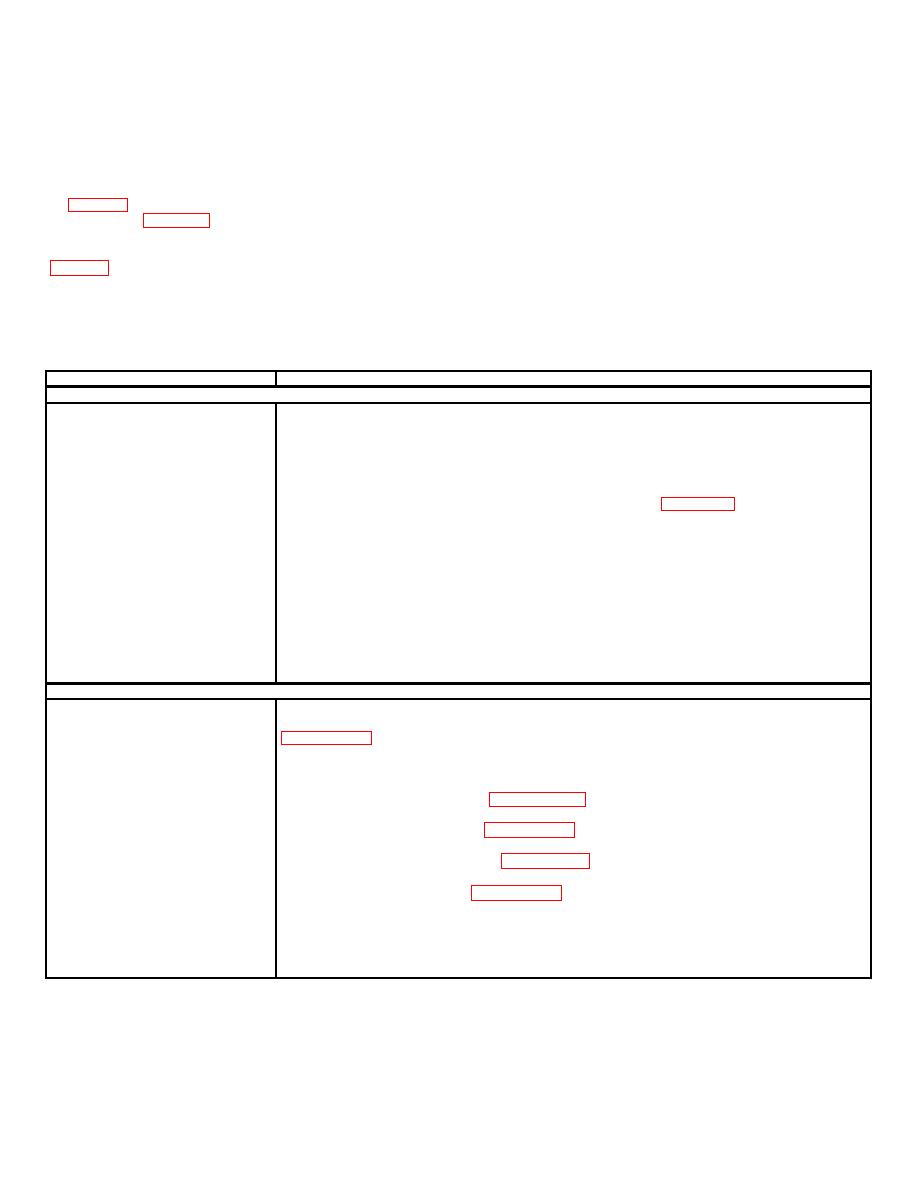

Table IV. Periodic Inspection and Service

Item

Inspection and Service

DAILY

1. Hydraulic reservoir

Check fluid level; refill as required.

2. Fuel Tank

Check level; refill as required.

3. Control Panel

Check that all controls move freely and that all handles are securely in place. Check that

instrument glasses are intact. Test indicators (5 and 10, figure 3-1) by pressing inward.

Indicators shall light when pressed. Replace lamp in indicator if required.

4. Housing interior

Check all wiring for breaks, worn insulation, and loose connections. Check all plumbing for loose

fittings and leaks.

5. Engine

Check oil level in crankcase.

6. Battery

Check electrolyte level.

7. Trailer

Check tire pressure; inflate as necessary to 65 psi. Check operation of hand brake lever.

50 HOUR INSPECTION

1. Fuel System

Check for loose fittings that might cause fuel leakage. Check and clean fuel filter.

See

2. Engine:

a. Crankcase

Drain and refill with fresh oil. See paragraph 4-20.

b. Oil filter

Clean and replace element. See paragraph 4-4.

c. Air Cleaner

Check and service air cleaner. See paragraph 4-5.

d. Spark Plugs

Check condition and gap. See paragraph 4-6.

e. Fan Belt

Inspect fan belt for frays and cracks; check belt tension.

3. Battery

Check specific gravity of electrolyte. Clean outer case and terminal connections.

4-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |