|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-4920-335-14

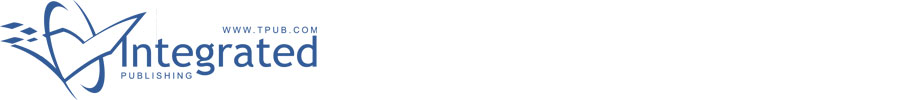

Table IV. Periodic Inspection and Service (Cont)

Item

Inspection and Service

4. Hydraulic System:

a. High Pressure Filter

Check for dirty or clogged element. See paragraph 4-7.

b. Low Pressure Filter

Perform checkout as outlined in paragraph 4-8. Service filter as necessary. See paragraph 4-4.

100 HOUR INSPECTION

1. Fuel System

Clean and service fuel pump. See paragraph 4-10.

2. Engine:

a. Timing

Check ignition timing. See paragraph 4-11.

b. Magneto points

Check magneto point condition and gap. See paragraph 4-12.

3. Thermoswitch

Check for proper temperature response. See paragraph 4-14.

4. Hydraulic Reservoir

Drain and Clean. See paragraph 4-15.

d. Check condition of bowl gasket and replace if

b.

Replace badly worn or cracked spark plugs.

necessary. Reassemble parts and open fuel valve.

c. Check and adjust spark plug gap. Gap should be

4-4. SERVICING ENGINE OIL FILTER. Service the engine oil

0.030 inch.

filter (9, figure 1-3) as follows:

d. Install spark plugs. Plug thread is 18 millimeter.

a.

Remove cover and cover gasket.

Tighten spark plugs to 25-30 foot pounds torque.

b. Remove cartridge. Clean out sludge from filter body.

4-7. SERVICING HIGH PRESSURE FILTER. If filter element

Do not remove spacer from center tube.

of high pressure filter (5, figure 1-3) is clogged or dirty, replace

element as follows:

c.

Install new cartridge and cover gasket. Install cover.

a. Cut safety wire and unscrew element case from

d. Add oil to compensate for filter. Run engine for five

bottom of filter head.

minutes and check for leaks. Recheck oil level.

b. Remove old element and thoroughly clean case.

4-5. SERVICING AIR CLEANER.

Service the engine air

Install new element in case.

cleaner (11, figure 1-3) as follows:

c. Thread case with element into bottom of filter head.

a. Loosen clamp screw and remove bowl from bottom of

Secure with safety wire.

cleaner.

4-8. CHECKING LOW PRESSURE FILTER. Perform the

b. Clean bowl and refill with oil, Military Specification

following low pressure filter (7, figure 1-3) condition checkout

MIL-L-2104 to oil level line. Install bowl to bottom of cleaner

while Test Stand is in operation with flow set at 10 gpm.

and secure with clamp screw.

a. Place pressure selector valve (12, figure 3-1) in

c. Remove precleaner from top of cleaner assembly and

FILTER INLET position. Observe reading on low pressure

empty accumulated dirt. Do not use oil or water in precleaner.

gage (9). Record this reading.

d. At least once a year, remove air cleaner from engine

b. Place selector valve (12) in FILTER OUTLET position.

and wash element (not removable) in solvent to clean out

Observe reading on low pressure gage (9). Record this

accumulated dust and dirt.

reading.

4-6. SERVICING SPARK PLUGS. Service engine spark plugs

c. Subtract second reading from first reading. The result

as follows:

of this subtraction is the pressure drop across the low pressure

filter. A pressure drop of 20 psi or more indicates a clogged

a. Remove spark plugs

from

engine

and

clean

filter element. Replace filter element as outlined in paragraph

thoroughly inside and out.

4-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |