|

|||

|

|

|||

|

Page Title:

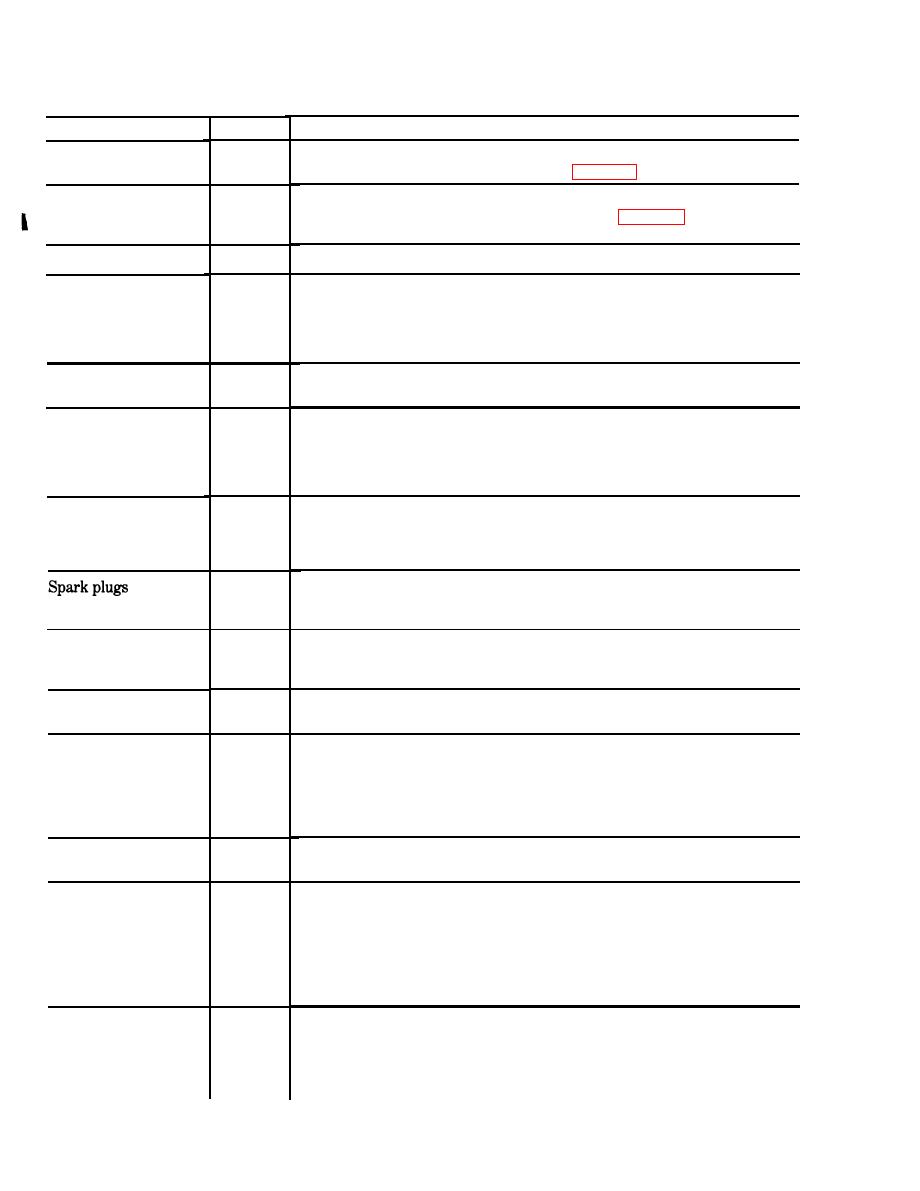

Table 3-2. Intermediate Inspection Requirements |

|

||

| ||||||||||

|

|

TM 55-4920-405-13&P

Table 3-2. Intermediate Inspection Requirements

Requirements

Period

Item

Check general appearance of test stand, paying particular attention

50 hr

General

to cleanliness. perform services listed in table 3-1.

Check for missing or damaged lubrication fittings and for indications

50 hr

Lubrication fittings

of improper lubrication. Lubricate according to table 3-5. Replace

missing or damaged fittings. Correct all oil or grease leaks.

Inspect oil level in engine crankcase. Check for oil leaks.

50 hr

Inspect for leaks, loose mounting hardware, and defective gaskets.

50 hr

Manifold

Tighten loose mounting hardware. During first weekly servicing of

new or reconditioned engine, let engine warm up to normal

operating temperature and tighten all loose bolts between 25 and 32

ft-lb torque.

Inspect for leaks, corrosion, loose mounting hardware, and defective

50 hr

gaskets. Tighten loose mounting hardware.

If engine valves are noisy, or loss of power is noticed, inspect valve

50 hr

Valve mechanism

mechanism. Remove valve covers and adjust valve lifter clearance

as needed. Correct intake valve lifter clearance is 0.0080 inch; ex-

haust valve lifter clearance is 0.0160 inch. Replace cover gaskets as

necessary.

Inspect ignition magneto for loose mounting bolts and loose wiring

50 hr

Magneto

connections. Correct any defects. Remove end cap and inspect

distributor cap for cracks and corroded terminals. Check breaker

point gap; correct gap is 0.015 inch at full separation of points.

Inspect for loose spark plugs, poor connections, and dirty or broken

50 hr

insulators. Replace damaged spark plugs. Clean dirty spark plugs.

Set spark plug gap to 0.0300 inch.

Check for loose mounting hardware. Examine brushes, brush holders,

50 hr

Starter motor

and sprinngs. Inspect commutators for dirt and scoring. Correct or

report defects.

50 hr

Check for loose mounting hardware, and loose electrical connections.

Correct defects.

Check to ensure roper operation, tight electrical connections, and

50 hr

Voltage regulator

firm mounting. Voltage regulators should allow appreciable charge to

battery after starter is used. After battery is fully charged. AM-

METER should read only a slight charge. Tighten loose mounting

hardware and electrical connections. Adjust or replace defective

voltage regulator.

Inspect control panel for loose mounting hardware and missing shock

50 hr

Control panel

mounts.

50 hr

Check to see that all gages indicate correctly and that glass is not

Gages and meters

cracked or broken. Tighten loose mounting hardware and hydraulic

connections. Replace any defective or damaged gage.

Check to see that all meters are tightly mounted and operate proper

ly. Check that glass is not cracked or broken and pointers are not

bent or broken. Tighten loose electrical connections and mounting

hardware. Replace any defective or damaged meter.

Inspect all control valves for packing leaks. Check to see that the

50 hr

Control valves

operate properly. See that handwheels are tightly mounted. Tighten

packing, or replace if necessary. Replace any defective or damaged

valve.

Change 2

3-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |