|

|||

|

|

|||

|

Page Title:

Section II. INSPECTIONS AND SERVICING |

|

||

| ||||||||||

|

|

TM 55-4920-405-13&P

Section II. INSPECTIONS AND SERVICING

3-4. INSPECTIONS. Refer to table 3-1 for daily

NOTE

inspection requirements. Daily inspections should

be performed before and/or after each day's opera-

tion. Intermediate and periodic inspections (tables

Keep all foreign matter out of lubri-

50 and 100 hours.

cants. Do not leave lubricant con-

3-5. SERVICING. Refer to table 3-4 for daily

tainers open any longer than neces-

servicing requirements, and to table 3-5 for a

sary. Store lubricants in a clean,

list of lubricants to be used.

dry area.

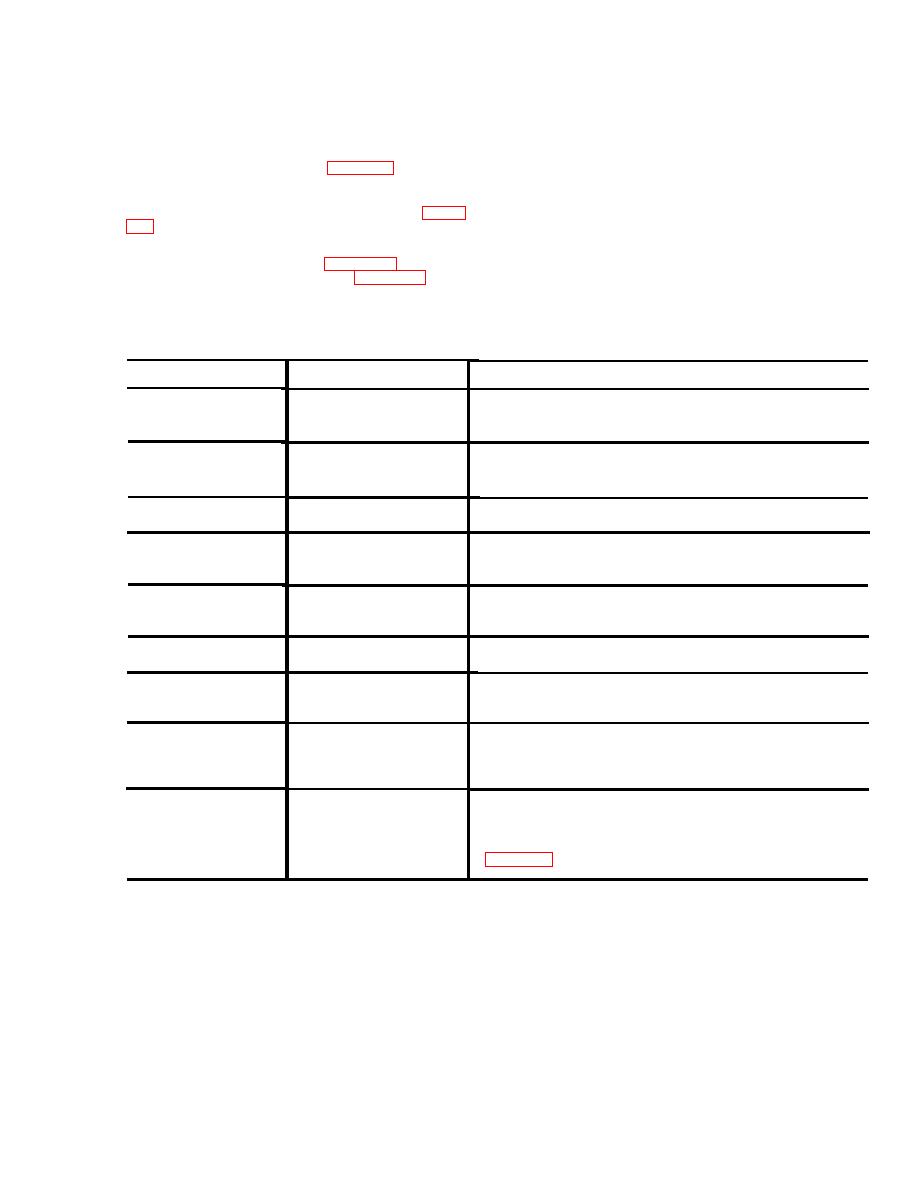

Table 3-1. Daily Inspection Requirements

Item

Period

Requirements

Preinspect/postinspect

Hydraulic reservoir

Check fluid level; add fluid as needed. Inspect for leaks.

Check hydraulic line connections for loose connections

and damage. Correct or report defects.

Preinspect/postinspect

Fuel system

Check fuel level; add gasoline as needed. Inspect for

leaks. Check fuel lines for loose connections and

damage. Correct or report defects.

Fuel strainer

Inspect bowl of strainer for dirt or water; clean as

Preinspect/postinspect

needed. Correct or report defects.

Preinspect/postinspect

Engine

Check oil level; add oil as needed. Inspect for oil leaks

near oil filter and crankcase drain plug. Correct or

report defects.

Battery

Preinspect/postinspect

Check electrolyte level; add water as needed. Inspect

for loose or broken connections, and excessive cor-

rosion. Correct or report defects.

Cabinet interior

Preinspect/postinspect

Check electrical wiring for breaks, worn insulation,

and loose connections. Correct or report defects.

Preinspect/postinspect

Trailer

Check tires for 60 PSI pressure; inflate as needed.

Inspect tires for deep cuts and excessive wear. Cor-

rect or report defects.

Control panel gages

Preinspect/postinspect

Check for broken glass, bent indicating needles, or

and controls

other obvious defects. Check that all controls oper-

ate smoothly and are tightly mounted. Correct or

report defects.

Test stand

Postinspect

Start and operate test stand and check for hydraulic

leaks. Check to make sure that 3000 PSI hydraulic

pressure can be obtained at maximum GPM flow.

Check temperature and flow indicators. (Refer to

chapter 2, section II.)

3-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |