|

|||

|

|

|||

|

Page Title:

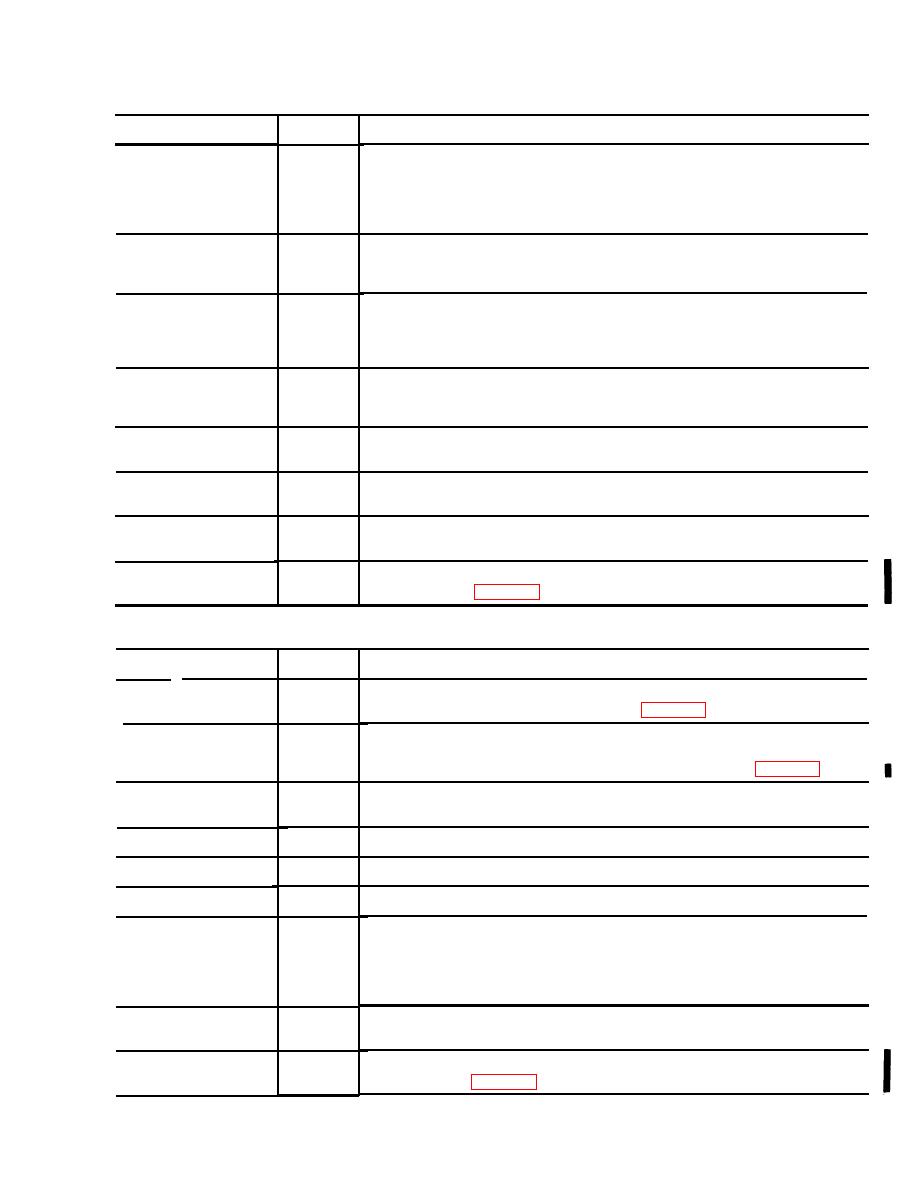

Table 3-2. Intermediate Inspection Requirements Continued. |

|

||

| ||||||||||

|

|

TM 55-4920-405-13&P

Table 3-2. Intermediate Inspection Requirements Continued.

Period

Item

Requirements

Inspect all tires for underinflation, abnormal or uneven wear, cuts,

Tires

50 hr

embedded foreign matter, and missing valve caps. Remove em-

bedded foreign matter. Replace cut or worn tires. Ensure that all

tires are inflated to correct pressure (60 PSI) and that all valve caps

are in place.

50 hr

Wheels

Inspect for loose wheel mounting bolts. Inspect wheel bearings for

proper adjustment. Tighten loose wheel bolts and adjust wheel

bearings as required.

Inspect axle assemblies for loose mounting and misalignment. Inspect

Axle

50 hr

springs for cracks, breaks, and weakened condition. Tighten all axle

mounting bolts. Align front wheels as required. Replace defective

springs.

50 hr

Brake assembly

Check brake assembly for unsatisfactory braking action. Check

brake rods for loose mounting. Tighten all brake assembly mounting

hardware and adjust brakes as required.

50 hr

High pressure filter

Inspect filter assembly for dirt or clogged condition causing

excessive pressure drop. Replace dirty or clogged filter element.

assembly

Inspect thermoswitch for correct temperature response and for loose

Thermoswitch

50 hr

mounting. Replace defective or damaged thermoswitch.

50 hr

Low pressure filter

Inspect falter assembly for dirt or clogged condition causing

excessive pressure drop. Replace dirty or clogged filter element.

assembly

Inspect air cleaner for accumulated dirt. Clean and service if

50 hr

Engine air cleaner

necessary. (See table 3-5).

Table 3-3. Periodic Inspection Requirements

Period

Requirements

Item

Inspect test stand for general appearance, paying particular attention

General

100 hr

to cleanliness. Perform services listed in table 3-1.

Inspect for missing or damaged lubrication fittings and for indications

100 hr

Lubrication fittings

of improper lubrication. Replace missing or damaged fittings. Cor-

rect all oil and grease leaks. Lubricate in accordance with table 3-5

Inspect oil level in engine crankcase. Inspect for oil leaks. Add oil as

100 hr

necessary. Correct all oil leaks.

Oil seals

100 hr

Inspect for damaged or defective oil seals.

100 hr

Inspect identification plates and markings for illegibility.

Markings

Inspect for chipped paint and exposed and rusty metal.

100 hr

Paint

Inspect engine cylinder head for leaks, loose mounting bolts, and

100 hr

Cylinder head

defective gaskets. Tighten loose mounting hardware. (During first

weekly servicing of new or reconditioned engine, let engine warm

up to normal operating temperature and tighten all loose bolts to be-

tween 25 and 32 ft-lb torque.

100 hr

Inspect for leaks, loose mounting hardware, and defective gaskets.

Manifold

Tighten loose mounting hardware.

Inspect air cleaner for accumulated dirt. Clean and service if

100 hr

Engine air cleaner

necessary (See table 3-5).

Change

2

3-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |